The wide variety of indirect restorative techniques currently available require healthy gingival tissues, tooth preparation appropriate for the intended restoration, provisional restorations with accurate margins, and an impression that can record adequate details of the preparation. The margins of the preparation require retraction of the gingival tissues in an atraumatic fashion. Selection and use of appropriate impression materials are required to achieve optimal performance. The material should reliably capture the prepared teeth, the adjacent teeth, the opposing arch, and the gingival tissues.

Shavell used the term “biologic impression” to mean impressing the dentition and the surrounding soft tissues in a natural state in relation to each other. In order to achieve this, two impressions often are required. The first will capture the detail of the prepared tooth with the tissues adequately deflected to delineate the margins. The second impression is with the final restoration in position and the soft tissue in its normal position. This allows the laboratory to achieve the proper emergence profile of the restoration.1

An ideal impression material should possess the following attributes: it should not shrink during polymerization or during shipment; the color of the impression material should clearly delineate margins; it should possess adequate tear strength; there should be no distortion upon removal; it should capture good detail of the preparation; it should be biocompatible/nontoxic; and it should have a pleasant odor and taste. Additional features are adequate working time, short set time, long shelf life, ability to pour multiple times without loss of detail, and easily disinfected.2

Prior to selection of the impression material, a choice must be made between stock and custom trays. Custom trays are easy to position in the mouth, don’t require any modification such as wax, and will not impinge on soft tissue. Stock trays can be used more reliably than in the past due to sufficient stiffness and stability. Full-arch trays are the best to minimize occlusal corrections chairside, but quadrant trays are acceptable for 1 or 2 units. An accurate interarch relationship with triple trays can be achieved for 1 or 2 units if placed carefully to eliminate any distortion of the tray during closure in centric.1

Impression materials can be categorized depending on their viscosity, hydrophilicity, and setting time.3 The viscosity describes the flow of unset impression material. A low-viscosity material (wash) is used to capture fine detail of a preparation and the surrounding soft tissue. A finely tapered tip is attached to a conventional impression syringe or attached to an automixing syringe in order to deliver the material precisely into and around the preparation and sulcus. The mixing tip also serves to decrease the viscosity by shear thinning.2 A more viscous material mixed simultaneously is used to push the light body in close approximation with the area being impressed. Medium-viscosity (monophase) materials can be used alone or in conjunction with light body. Monophase material can also be used with high-viscosity or putty materials and dispensed with a syringe. High-viscosity and putty materials lack the requisite flow to adapt to the preparations and the gingival sulcus, and must be used in conjunction with a less viscous material.3

|

|

|

Figure 1a. Hydrophilic materials have a high affinity for water. |

Figure 1b. Absorbing water may lead to dimensional instability. |

|

|

Figure 2a. Moisture in the sulcus prevents capturing surface detail of a preparation. |

|

|

|

Figures 2b and 2c. Hydroactive materials are rendered more hydrophilic through the addition of surfactants. This allows the impression material to come in close contact with the preparation. |

Figure 3. A double-cord technique allows adequate displacement of the soft tissue and prevents its collapse. |

The choice of impression material may be affected by its affinity to water (hydrophilicity).3 A hydrophilic material can capture excellent surface detail due to its wetting ability, but imbibing excess moisture can create dimensional instability (Figures 1a and 1b).

Hydrophobic materials are repelled by water, and due to increased contact angle they are not able to capture surface detail adequately. The area must be dry to achieve an adequate impression. Hydroactive materials are hydrophobic materials that have been modified by the addition of surfactants to make them more hydrophilic (Figures 2a to 2c). However, unlike true hydrophilic materials, water is displaced rather than being absorbed. This provides better dimensional stability.3

TYPES OF IMPRESSION MATERIAL

Polyether materials are very hydrophilic, which enables them to capture surface detail readily and be poured simply with gypsum products. Polyethers are intrinsically hydrophilic as a result of the polarity of the polyether molecule.4 They remain dimensionally stable for a week if in a dry environment, but high humidity or disinfecting solutions can lead to dimensional changes. The original materials were very rigid and had a poor taste. Advanced polyethers such as P2 (Heraeus Kulzer) have a neutral odor and taste but are naturally hydrophilic.2 The introduction of Impregum Penta Soft (3M ESPE) improved the taste and made it easier to be removed from the mouth.

Polyvinyl siloxanes (PVS) generally consist of 2 components: a base material and polymerization initiators. Condensation reaction silicones (C-silicones) release alcohol during condensation, resulting in shrinkage, and in order to increase accuracy the material should be poured within one hour. Additional reaction silicones (vinyl polysiloxane [VPS]) contain a vinyl group and a platinum catalyst that serves to eradicate the alcohol release.5 VPS materials enjoy extensive usage due to their dimensional accuracy, minimal shrinkage after long-term storage, excellent elastic recovery, ease of use, and the capability of multiple pours from one impression.2,6 VPS materials can be used for both fixed and removable prosthodontics.

The dimensional accuracy of any impression material depends on the time from the initial impression until it is poured. VPS materials do not liberate any byproducts that may contribute to inaccuracies. The main limitation to VPS materials has been the inherent hydrophobicity of the aliphatic hydrocarbon groups that envelop the siloxane bond.1 This may result in two problems. The surface free energy of the polymerized VPS material results in an increased contact angle forming when the impression is poured with gypsum stone. The other problem arises as a result of the free energy present in the unpolymerized material and its inability to wet the hard and/or soft tissues being impressed.2 Manufacturers have included surfactants to increase the wettability of these materials. These nonionic surfactants will augment the wettability and reduce surface bubbles. Contact angle measurements are used to ascertain the degree of wettability intraorally and during model fabrication. However, “hydrophilic” impression materials may continue to be hydrophobic in the unpolymerized state, and they will not properly capture detail on wet surfaces, but the surfactants have enhanced VPS wettability with gypsum products. In order for the surfactants to work, they must migrate to the surface, and initially the material isn’t hydrophilic.6 Latex gloves and metal ions in astringents can prevent the polymerization of VPS materials.3

MATERIAL, TECHNIQUE, AND CASE REPORT

Material

Flexitime Xtreme is a new addition to Heraeus Kulzer’s impression materials, and it can be used for crowns, bridges, and other indirect restorations. It has the added advantage over the original Flexitime of having a working time of 30 to 90 seconds and an intraoral set time of about 90 seconds. The material sets once placed in the patient’s mouth. Heraeus Kulzer has designated this feature as Advanced ThermaSense.

Technique

|

|

|

Figure 4a. A new mixing tip is placed onto a cartridge of Flexitime Xtreme Heavy Tray material, and the impression tray is loaded. |

Figure 4b. A thin layer of Flexitime Xtreme Correct Flow wash material is applied onto the Flexitime Xtreme Heavy Tray material. |

|

|

|

Figure 4c. A syringe tip is placed onto the mixing tip on the Flexitime Xtreme Correct Flow cartridge, and wash material is syringed around the preparation. |

Figure 4d. To avoid incorporating air voids, keep the tip of the syringe embedded in the Flexitime Xtreme Correct Flow as it is expressed circumferentially around the tooth. |

|

|

|

Figure 4e. Seat the impression tray in the mouth and stabilize for 90 seconds. |

Figure 5. Patient presented with a fractured buccal cusp on tooth No. 13. |

Upon completion of the preparation, the tooth must be prepared for the impression. Retraction of the soft tissue is required in order to expose a subgingival margin to the impression material. A variety of techniques are available including cord, electrosurgery, soft-tissue laser, and paste retraction. A double-cord technique is useful for preparations that extend deeper in-to the sulcus (Figure 3). The tip of the packing instrument should be angled toward the starting point. Stopping bleeding (hemostasis) is necessary for an accurate impression. Hemostasis can be achieved by a variety of chemical agents (eg, ferric sulfate, aluminum chloride). The selected hemostatic agent should not interfere with the set of the chosen impression material.

Apply adhesive to the impression tray. Place a new mixing tip onto a cartridge of Flexitime Xtreme Heavy Tray material and load the tray (Figure 4a). Place a new mixing tip onto a cartridge of Flexitime Xtreme Correct Flow material. Apply a thin layer of Flexitime Xtreme Correct Flow wash material onto the Flexitime Xtreme Heavy Tray material (Figure 4b). Place a syringe tip onto the mixing tip on the Flexitime Xtreme Correct Flow cartridge and syringe wash material around the preparation (Figure 4c). Keep the tip submerged to avoid air bubbles (Figure 4d). Seat the impression tray in the mouth and stabilize for 90 seconds (Figure 4e). When set, remove and evaluate the final impression.

CASE REPORT

|

|

|

Figure 6. The proper shade was obtained. |

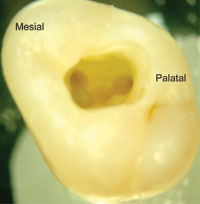

Figure 7. Impression with Flexitime Xtreme captured necessary detail. |

|

|

| Figures 8 and 9. The final restoration demonstrates a good blending with surrounding tooth structure. |

The patient presented with a fractured buccal cusp on tooth No. 13 (Figure 5). The old amalgam was removed. The buccal area of the fracture was beveled so that a blend between the restoration and the tooth could be achieved. The last 0.5 mm of the restoration was translucent to allow the underlying dentin to show through and eliminate or minimize any demarcation of the interface. An alternative technique would be to place a full veneer preparation on the buccal surface and extend the preparation to the gingival margin. Care must be taken to ascertain the appropriate path of insertion. The shade was obtained (Figure 6). The impression with Flexitime Xtreme captured necessary detail (Figure 7). The restoration was luted with OptiBond Solo Plus (Kerr) and Nexus 2 (Kerr). The final restoration demonstrated a good blending with surrounding tooth structure (Figures 8 and 9). Ideally, quadrant dentistry would have allowed the replacement of the restorations in the 2 adjacent teeth, but financial constraints prohibited this from being accomplished.

CONCLUSION

The introduction of recently updated impression materials has allowed an increased degree of accuracy and rapid implementation. However, properly preparing the tooth (teeth) and soft tissue for the impression is still important. The material and technique described allows the achievement of an accurate impression, good taste, ease of use, and shortened intraoral time for increased patient comfort.

References

1. Ahmad I. Protocols for Predictable Aesthetic Dental Restorations. Oxford, England: Blackwell Publishing; 2006:165-184.

2. Burgess JO. Impression material basics. Inside Dentistry. October 2005:30-33.

3. Pitel ML. Successful Impression Taking. First Time. Every Time. Armonk, NY: Heraeus Kulzer; 2005: C-C14.

4. Walker MP, Petrie CS, Haj-Ali R, et al. Moisture effect on polyether and polyvinylsiloxane dimensional accuracy and detail reproduction. J Prosthodont. 2005;14:158-163.

5. Blatz MB, Sadan A, Burgess JO, et al. Selected characteristics of a new polyvinyl siloxane impression material: a randomized clinical trial. Quintessence Int. 2005;36:97-104.

6. Petrie CS, Walker MP, O’Mahony AM, et al. Dimensional accuracy and surface detail reproduction of two hydrophilic vinyl polysiloxane impression materials tested under dry, moist, and wet conditions. J Prosthet Dent. 2003;90:365-372.

Dr. Trushkowsky has lectured at most of the major dental meetings and internationally. He is a Fellow in the AGD, the Academy of Dental Materials, the International College of Dentists, the American College of Dentists, and the Pierre Fauchard Academy. He is a member of the Academy of Osseointegration, the Academy of Cosmetic Dentistry, the International Association of Dental Research, the American Prosthodontic Society, and the Academy of Operative Dentistry. He is a senior consultant for the Dental Advisor and a CRA evaluator. He wrote a chapter on direct composites in Esthetic Dentistry and a chapter on complex single-tooth restorations in Dental Clinics of North Amer-ica. He has published more than 80 articles and abstracts in a variety of journals and magazines and is a clinical assistant professor in the New York University College of Dentistry postgraduate aesthetic program. He also has 2 patents on devices to aid in posterior composite placement, and can be reached at (718) 948-5808 or composidoc@aol.com.