An international team of doctors has developed a technique to create and position titanium mesh to improve guided bone regeneration in dental implant treatment after encountering a patient with several missing front teeth due to an injury that resulted in a large gap referred to as a bony defect.

The doctors began with a bone graft, followed by dental implants that would support the replacement teeth. They created a virtual 3-D model of the patient’s mouth and bony defect. Then, with a computer program, they determined the correct position and placement of the bone graft based on the desired location of the replacement teeth.

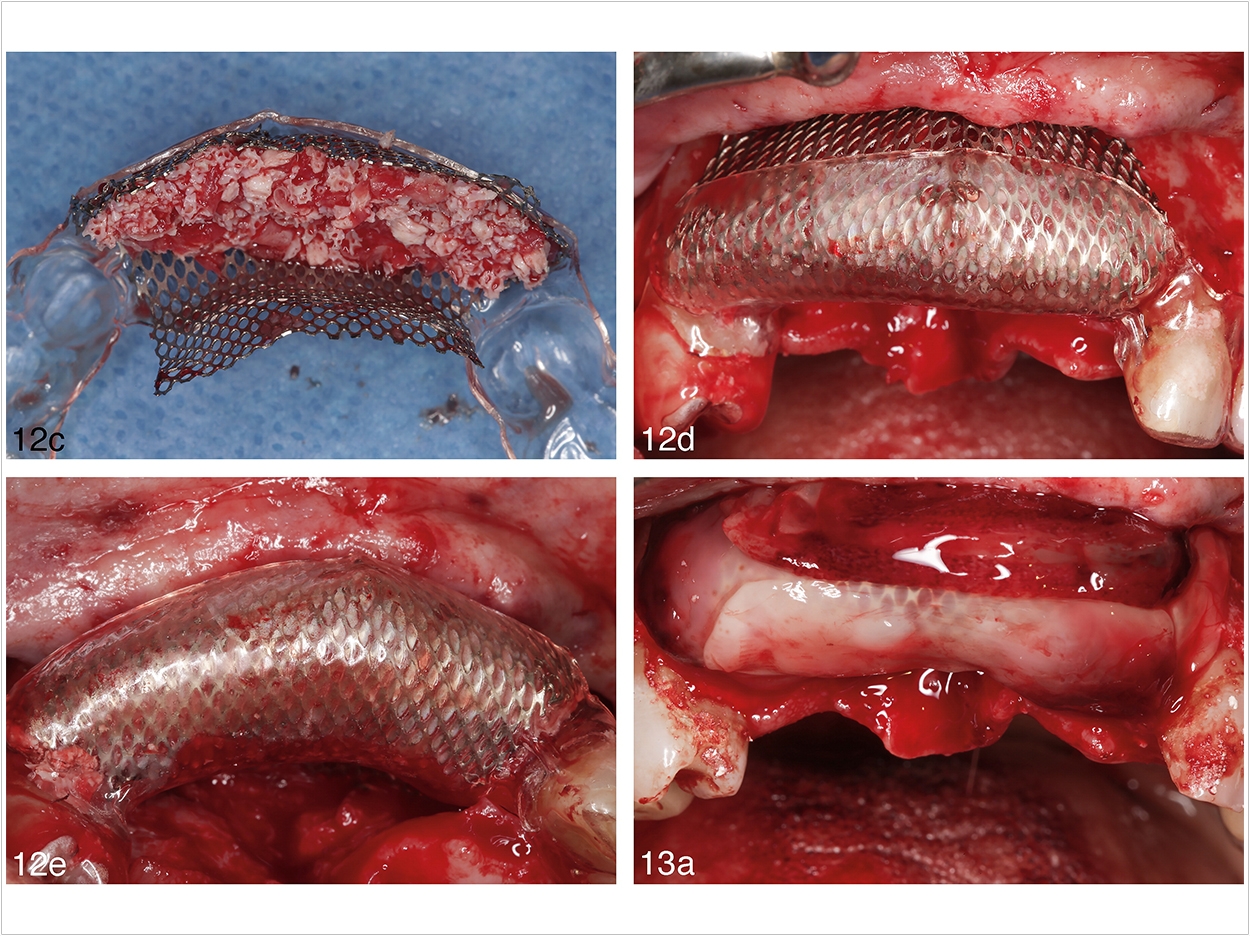

Next, the doctors 3-D printed a model and fabricated the titanium mesh to fit the intended bone position and volume. They then filled the titanium mesh with bone harvested from a remote location in the patient’s mouth and secured it in the site of the missing teeth with fixation screws.

By digitally creating the titanium mesh, the doctors ensured that the material was the precise shape and volume needed for the patient’s bony defect. This reduced the chance that the titanium mesh would cause an unfavorable outcome during healing, including mesh exposure and irritation.

During surgery, the doctors ensured the proper placement of the titanium mesh and bone graft with a positioning jig fabricated from a clear plastic mold that used the existing teeth to hold the mesh in place while it was being secured. Finally, to improve wound healing and bone stability, the doctors applied fibrin membranes rich in platelets.

“Virtual 3-D planning has become more popular in recent years when planning for implant placement,” said Aladdin J. Al-Ardha, BDS, MS, an associate professor of restorative dentistry at the Loma Linda University School of Dentistry. “Our technique ensures precise augmentation of the bony defect and an accurate positioning of the mesh.”

The doctors concluded that prefabrication of titanium mesh also reduces surgical time and ensures the location of replacement teeth will be correct. They say that future work is needed to improve the fabrication of the positioning jig as well as to determine the dental procedures for which the technique would be appropriate.

The article describing the technique, “Using Virtual Ridge Augmentation and 3-Dimensional Printing to Fabricate a Titanium Mesh Positioning Device: A Novel Technique Letter,” was published by the Journal of Implantology.

Related Articles

Exposed Titanium Mesh Removal Improves Implant Procedures

Calcium Ions May Improve Titanium Implant Integration

Titanium Implant Alternative Uses the Patient’s Own Dentin