3-D printing is transforming dentistry as it enables dentists to create crowns, bridges, retainers, splints, surgical guides, dentures, and more all in their office in a matter of hours. In fact, SmarTech Publishing says 3-D printing will overtake subtractive milling and traditional analog fabrication processes by 2027.

Of course, many dentists may feel left behind by the rapid pace of these innovations. Rik Jacobs, vice president and general manager of dental solutions at 3D Systems, recently shared his insights about the technology and how it is impacting the dental profession.

Q: Could you tell us about your background in technology and 3-D printing?

A: I’ve been working in the dental industry for 20 years with a focus on bringing materials to market, specifically polymers, monomers, and thermoplastics. I became interested in 3-D printing around 2008. At this time, the production of hearing aids transformed from analog to digital, or 3-D printing, in a matter of two years.

Seeing the power of 3-D printing to transform production of these medical devices, I was inspired to learn everything I could about 3-D printing in an effort to make a positive impact on the dental industry. I partnered with TNO, an independent research organization based in the Netherlands, to design a 3-D printing technology for dental. This work resulted in a materials portfolio and the founding of the NextDent company in 2012. Ultimately, because of NextDent’s success as a dental materials provider, 3D Systems acquired the company in January 2017 to be an integral part of the 3-D printing solution they were developing specifically for the dental industry.

Q: Could you generally describe the current state of 3-D printing in dentistry?

A: 3-D printing is already demonstrating benefits in regards to many dental applications including dentures, long-term temporaries, orthodontic splints and retainers, surgical guides, trays, and models. We are seeing standalone technologies, such as software design solutions, as well as complete end-to-end workflows that combine the software, hardware, materials, and services. The widest adoption for 3-D printing is occurring in dental laboratories and clinics where digitalization has already been implemented.

Q: Many dentists may be put off by the newness of the technology. Could you tell us about the learning curve and the best strategies for dentists to learn how to use 3-D printing?

A: There is a learning curve, but it is far from insurmountable. The most important piece of advice I can give to any dental lab or clinic looking to integrate 3-D printing into their digital dentistry workflow is to work with an experienced partner. There are currently many resellers that offer training, service, and support to their customers. We are also seeing many schools and universities including 3-D printing and digital dentistry into their curriculum. This helps break down the barriers to adoption, because those technicians who are new to the workforce already have experience with the technology and know the benefits they can realize from using it.

Q: Another obstacle may be the investment in technology. Could you tell us about current price points, return on investment, and other equipment needed to use 3-D printing?

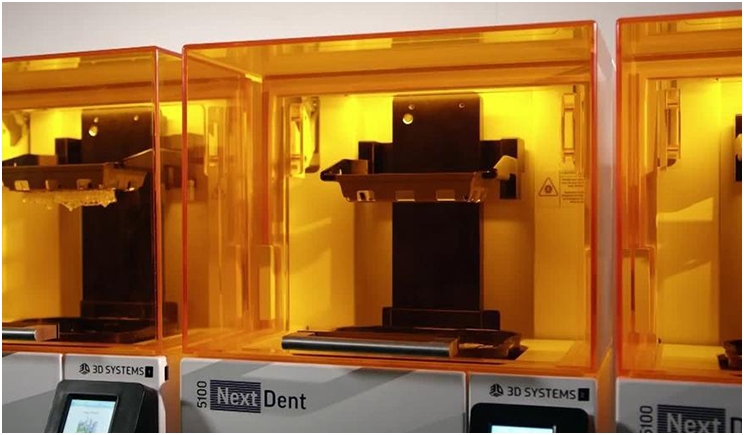

A: There are currently a variety of technologies and solutions available on the market for digital dentistry. The one I am closest to, of course, is the NextDent 5100 from 3D Systems. The 3-D printer, built on our Figure 4 technology, retails for $10,000. In addition to the printer and the appropriate materials based on indication, the technician also needs a post-curing device (the NextDent LC-3DPrint Box) as well as a bottle roller (the NextDent LC-3D Mixer). The total investment without scanning technology and software is approximately $12,500. When the system is properly implemented in a dental workflow, this can be earned back in about six months.

3D Systems’ NextDent 5100 digital dentistry solution is helping dental laboratories and clinics redefine their workflow and achieve improved accuracy (within 50 µm), repeatability, and productivity (faster than milling) with lower total cost of operation.

Q: Do you see any other obstacles to broader adoption of the technology?

A: I don’t believe there are any. Once dental labs and clinics see the tremendous benefits their competitors are realizing from the NextDent 5100 solution, it becomes a given that they need to adopt it as well to remain competitive.

Q: What kinds of applications does 3-D printing have in dentistry now, and how do you see these applications evolving or growing in the future?

A: Today, 3-D printing is already demonstrating benefits in regards to dentures, long-term temporaries, orthodontic splints and retainers, surgical guides, trays, and models. As more innovation happens in regards to dental 3-D printing materials, we will see addressable indications expand to include direct printing of dental implants as well as long-term crowns and bridges.

Q: Do you have any other comments on the future of the technology?

A: As with all technologies, digital dentistry solutions will continue to evolve based on new ways dental clinics and laboratories work with the technology and the number of indications they are able to address. However, from 3D Systems’ perspective, we have passed the tipping point and the NextDent 5100 is broadly implemented in the industry, with adoption continuing each day.

When used in conjunction with 3D Systems’ robust portfolio of certified NextDent materials, dental labs and clinics can address the broadest range of indications from a single printer available today. This plug-and-play solution integrates with the industry’s state-of-the-art intraoral scanning and software solutions, delivering a much more precise result than available with manual production.

The benefits of this revolutionary solution also extend to the patient, as it reduces both the time required to produce orthodontic and prosthodontic devices and the number of office visits needed to complete treatment. This end-to-end solution combining materials, technology, software, and services will help dental labs and clinics revolutionize their businesses.

Related Articles

Q&A: Dr. Jeffrey Shapiro and 3-D Printing in the Dental Office

3-D Printers Improve Production Inside the Dental Office

Simplifying Full-Arch Implantology With Digital Dentistry