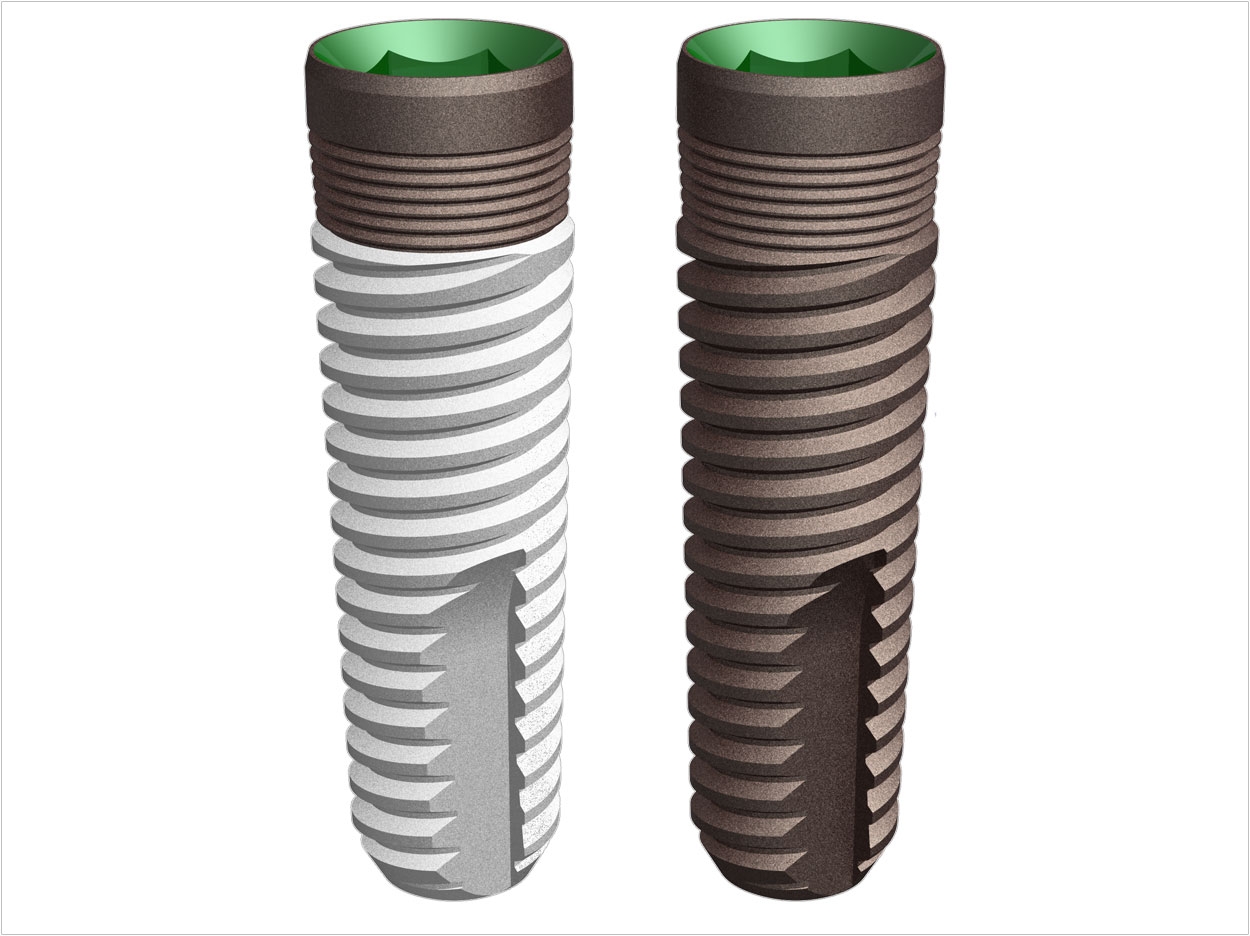

With an eye on market trends and input from academic and clinical professionals, American Dental Implant Corportion (ADI) has redesigned its entire product line. Its implants now feature precision microgrooves, higher flutes for improved bone threading, and color anodizing to improve platform compatibility. They include a first-state surgical cover screw, impression coping, and a .050-in/1.25-mm hex tool.

“The design geometry of dental implants at the crestal bone to soft tissue junction has been one of the great areas of research and advancement. Studies testing the attachment and adhesive strength of hard and soft tissue at this fragile interface have shown microgrooves to enhance hard and soft tissue stability both immediately and over time compared to a smooth or micro-abraided surface,” said Steven B. Lombardi, DMD, president of ADI.

“Crestal bone levels, bone to implant direct contact on a light microscopic level (osseointegration) and implant stability has been shown to be enhanced when microgrooves are present. Bone growth has been shown to be present inside the microgrooves,” Dr. Lombardi said. “It should be noted that ADI offers its historically proven design without microgrooves to any implant or restorative dentist who has that preference.”

All implants are original internal hex compatible and are offered in resorbable blast media (RBM) or hydroxylapatite (HA) surface. These products are compatible with many other systems in use, so required purchases of unique parts are minimal if necessary at all. Furthermore, the company calls its pre-mounted delivery system the most user-friendly delivery system in the industry.

Each implant is provided in an easily opened pouch. When opened by nonsterile circulating personnel, the pouch drops 2 sterile vials on the surgical tray following a sterile aseptic technique. In one motion, the surgeon unthreads the implant from the vial, which presents the implant ready to be threaded into the osteotomy. The implant is directed to the osteotomy and is threaded in digitally until drivers are required for additional torque.

When the implant is fully threaded into the osteotomy and the surgical checklist is completed, the first-stage surgical cover screw is unthreaded from its protector vial, where it is friction-locked on its own .050-in/1.25-mm hex driving tool. The cover screw is directed to the implant and threaded in to complete the surgical insertion.

“There is virtually no chance for dropped or mishandled items, and each implant provides the purchaser with a universal hex driver that can be cleaned and sterilized and used for the restorative phase or for other cases or be provided to the referring dentist,” said Dr. Lombardi. “At the time of surgery, the surgeon should be focusing on the case, and not on little confusing packaging singularities.”

ADI offers all prosthetic components for the complete restoration, including prepable abutments, custom abutments, zirconia abutments, and overdenture systems. It also offers a complete surgical sterilization kit for the placement of its full line of dental implants.

The autoclavable surgical container is made of surgical grade stainless steel and comes in 2 versions. The Introductory Surgical Kit includes only the products that are necessary for implant surgery. The Master Surgical Kit features all of the surgical items in addition to the prosthetic phase instruments.

ADI’s line is Zimmer compatible: 3.3, 3.7, tapered 3.7, 4.7, tapered 4.7, and tapered 6.0 mm. The proprietary 2-piece Skinny 2.4 implant, designed and developed for narrow ridge situations, is platform-compatible with Zimmer as well. ADI calls it the first true hybrid implant between a mini and a fully restorable implant, less than 3.0 mm in diameter while offering full prosthetic versatility via the standard internal hex restorative chamber.

The drilling sequence for the Skinny 2.4 uses a locator drill and a matched finial sizing drill. The locator drill has a groove mark at the 8-mm line. The final sizing drill offers a countersink feature with safety and other benefits. It comes in both an externally irrigated twist drill geometry and internally rigged spade drill geometry to suit the surgeon’s choice. This protocol and its components creates the safest, most precise, and most predictable osteotomy in the industry, Dr. Lombardi said.

“The Skinny 2.4 is also the foundation for the sequential bone compression technique. Unexpected soft bone (Type III and Type IV) can be found in all genders, races, ages, and locations in the oral anatomy. The protocol of this technique compresses unexpected soft bone in as little as 30 seconds of chair time,” Dr. Lombardi said. “The Skinny 2.4 very well could be called the Universal Dental Implant.”

For more information, call 800-511-0661 or visit americandentalimplant.com.