INTRODUCTION

The replacement of a full arch of failing teeth has long been seen as the panacea of implant dentistry. The All-on-4 protocol as described by Malo et al1 has shown excellent implant and prosthetic success rates. Traditional analog workflows included:

- Preliminary diagnostic impressions

- Diagnostic trial setup

- Surgical procedures, including analog impressions

- Try-in/bite verifications

- Insertion of temporary prostheses

These additional steps increase the overall time taken for prosthesis delivery as well as costs. Continuing development in additive manufacturing (3D printing) has resulted in predictably accurate prints. The resins used in contemporary 3D printing have been shown to have physical properties similar to milled polymethylmethacrylate (PMMA)2 and can now be printed on “desktop” printers.

In addition to the improved speed and accuracy of 3D printed restorations, the implementation of photogrammetry allows for the accurate capture of implant positions, ensuring the delivery of a completely passive prosthesis.3

The use of CAD software (exocad) enables rapid production of a digital file, which, when combined with all the relevant preoperative and intraoperative data, allows the clinician to quickly approve the case design and proceed to prosthesis fabrication. This case report describes a simplified, completely digital workflow for the provision of a full-arch temporary prosthesis within 24 hours.

CASE REPORT

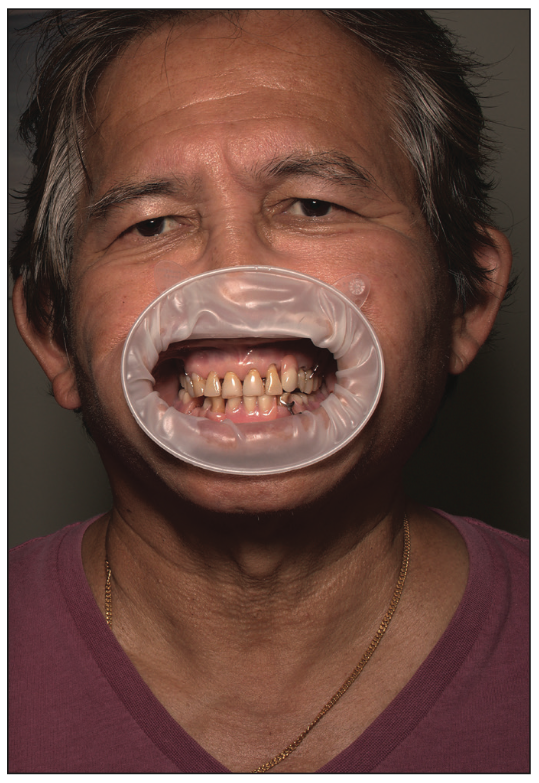

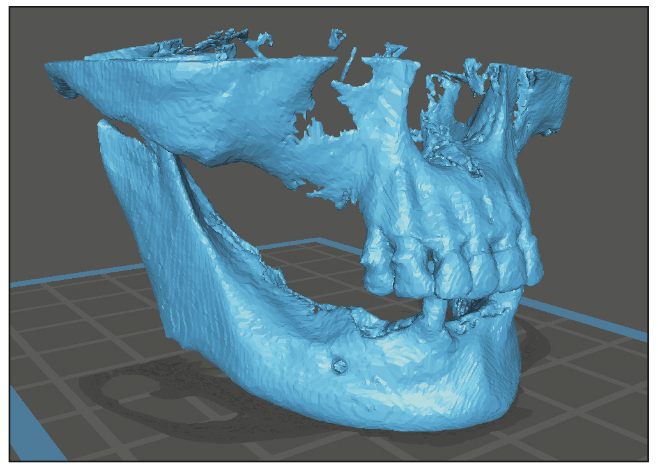

A patient presented with a partially dentate mandible and a failing acrylic lower partial denture (Figure 1) and requested a fixed solution with the specific desire of being “able to bite into an apple.” His existing vertical dimension of occlusion (VDO) was satisfactory, and the initial CBCT was performed with the patient in occlusion at this VDO (Figure 2). This pre-op CBCT will provide a reference for relating the postoperative CBCT back to the patient’s original vertical dimension. If any alterations are anticipated, it is important to perform these prior to the diagnostic CBCT either by addition of composite to existing teeth in dentate patients or by fabrication of a denture at the correct VDO in edentulous patients.

Figure 1. The patient presented with a partially dentate mandible and failing teeth Nos. 22 and 27.

Figure 2. Preoperative CBCT taken to document the original vertical dimension.

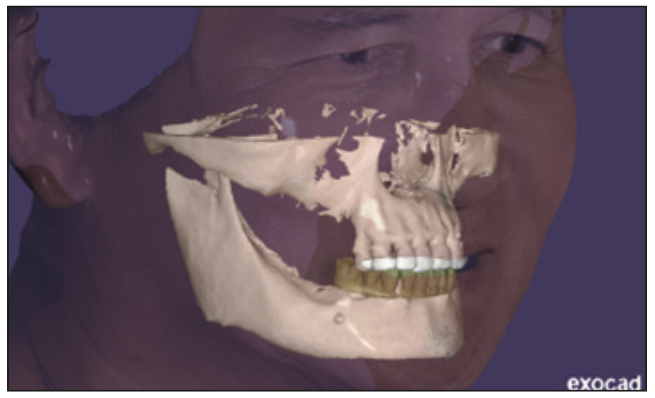

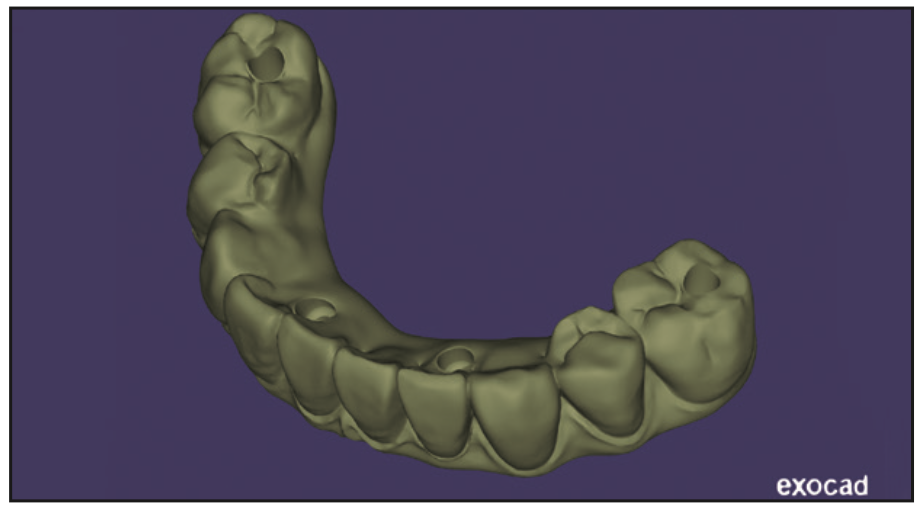

Figure 3. The exocad design file.

Additional diagnostic data collected at this appointment included intraoral scans (i700 [Medit]), DSLR photography, and a 3D face scan (Vectra Smile [JK Dental Group]). All of the diagnostic data was merged in exocad to create a digital patient (Figure 3).

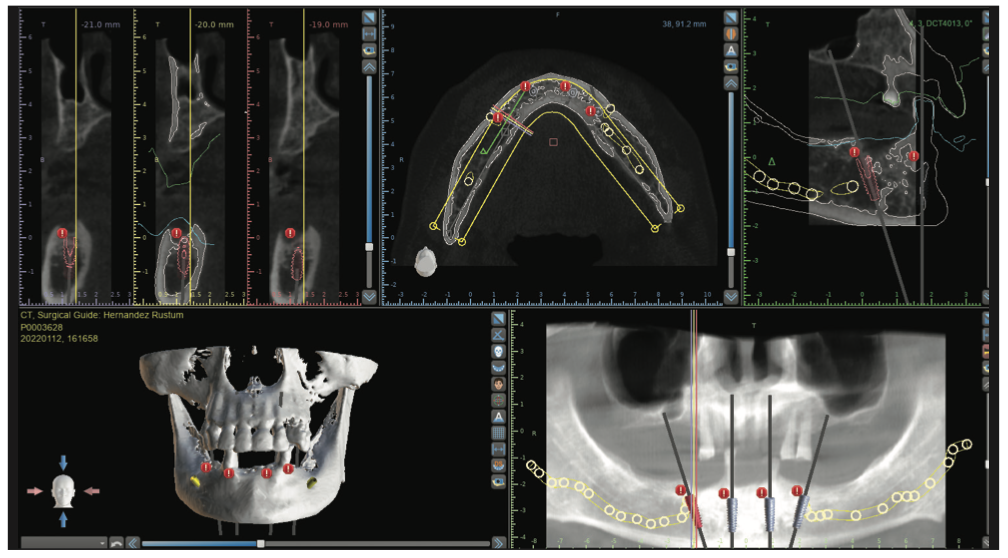

Implant planning was performed using Blue Sky Plan planning software (BlueSkyBio) to ensure adequate available bone was present to place and immediately load the implants (Figure 4). Freehand surgery was performed on the patient under IV sedation.

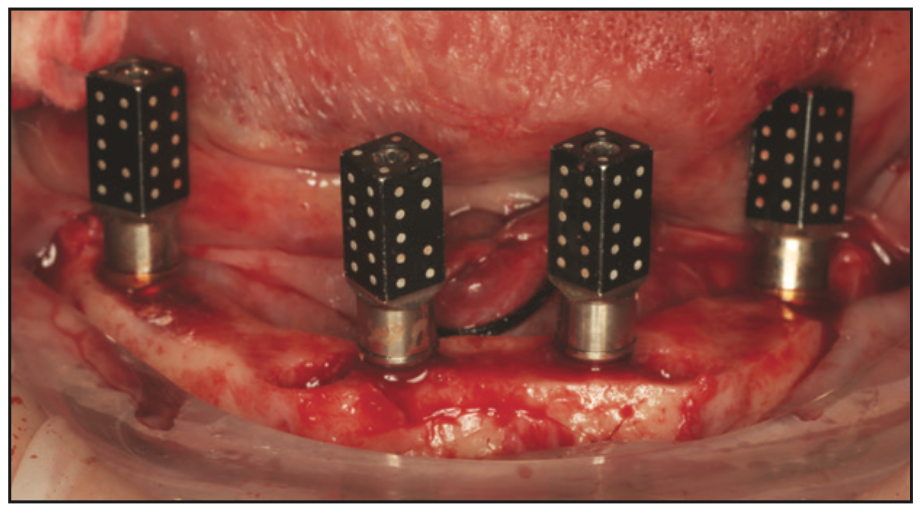

Once surgery was completed, and before surgical closure, iCam body scans were performed using Imetric 4D Imaging photogrammetry (Figures 5 to 7).

Figure 4. Surgical planning in Blue Sky Plan planning software (BlueSkyBio).

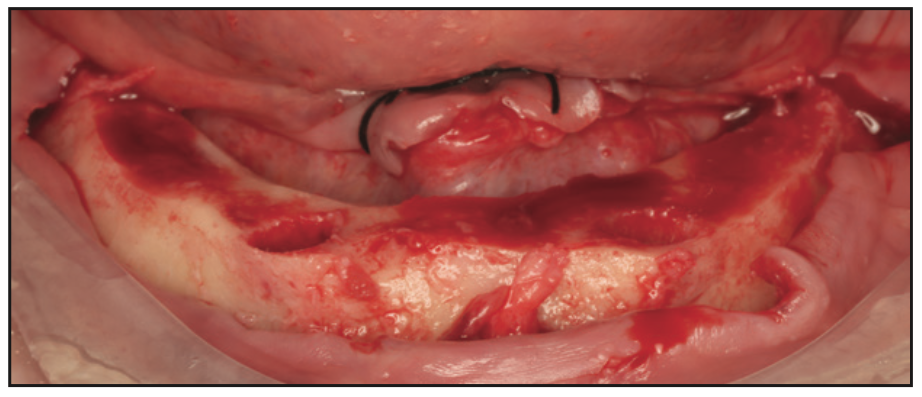

Figure 5. Mandible after alveolectomy for prosthetic space.

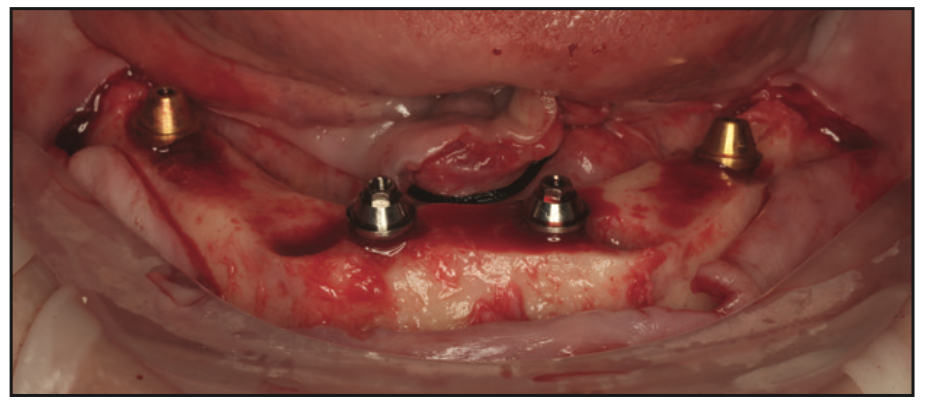

Figure 6. Implants placed.

Figure 7. Implants with iCam body scans (Imetric 4D Imaging photogrammetry) attached.

A post-op CBCT scan was taken to generate 2 STL files from DICOM data by altering thresholds:

- An STL of iCam reference scan bodies for stitching to soft tissue (increasing the Hounsfeld unit threshold).

- An STL of hard tissues to relate to pre-op CBCT within Imetric software (lowering Hounsfeld unit threshold).

All diagnostic data were aligned and exported to exocad for the generation of an STL file of the provisional prosthesis.

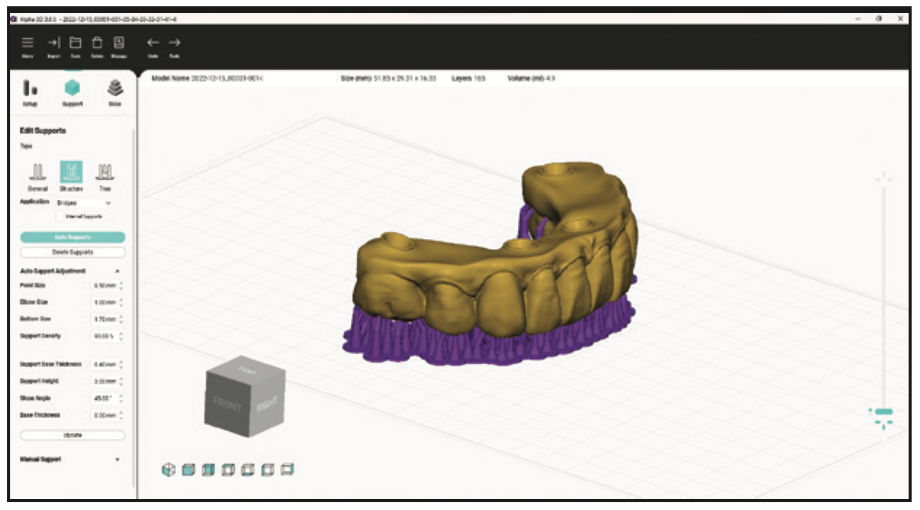

The prosthesis was designed in exocad CAD software (Figures 8 and 9), and 3D printing was performed on an Ackuretta Sol printer using Rodin Sculpture A1 Resin (Pac-Dent) following the manufacturer’s settings. Optimal support settings were generated by the AI software.

Figure 8. Prosthesis design.

Figure 9. Nesting in printing software.

Rodin Sculpture (Figure 10) is a new ceramic nanohybrid resin that streamlines the fabrication process while reducing manufacturing costs for both clinicians and dental laboratories. It is an FDA 510(k)-cleared, biocompatible, light-curable resin designed to be used with specific CAD/CAM systems in combination with manufacturer-validated 3D printing and light-curing devices. This new resin can be used to fabricate permanent full-contour crowns, inlays, onlays, and veneers. In addition, it can be used to fabricate All-on-X immediate prostheses, monolithic dentures, and split-file denture tooth arches. It is composed of the same resin components found in most restorative composites with the addition of a high concentration of true nano-ceramic fillers that provide brilliant radiopacity.

Rodin was chosen for its excellent mechanical properties coupled with its lifelike translucency. It offers the highest flexural strength and modulus of any long-term/permanent restoration and features lifelike aesthetics. It is also highly break-resistant, reducing the incidence of repairs and remakes.

After printing, the prosthetic was removed from the build plate, and the supports were removed (Figures 11 and 12). Next, it was carefully washed with isopropyl alcohol to remove excess uncured resin. The support tips were finished smooth with a low-speed handpiece and a finishing bur. The denture was then polished with pumice and acrylic polishing compound for a final finish.

Figure 10. Rodin Sculpture (Pac-Dent).

Figure 11. Printed prosthesis on build plate.

Figure 12. Prosthesis prior to cleaning.

Gingival staining and glazing were achieved using denture stain elixirs (Larry’s Magical Denture Elixirs [TAUB Products]) and Rodin Palette glaze for surface characterization (Figure 13). The prosthesis was then light-cured in the Ackuretta Curie unit.

The following morning, the provisional prosthesis was delivered with polymer-specific prosthetic screws. No occlusal adjustment was needed. When designing the prosthesis, care was taken to minimize cantilever length and respect minimum thickness around implant access channels.

Figure 13. Staining and glazing of prosthesis.

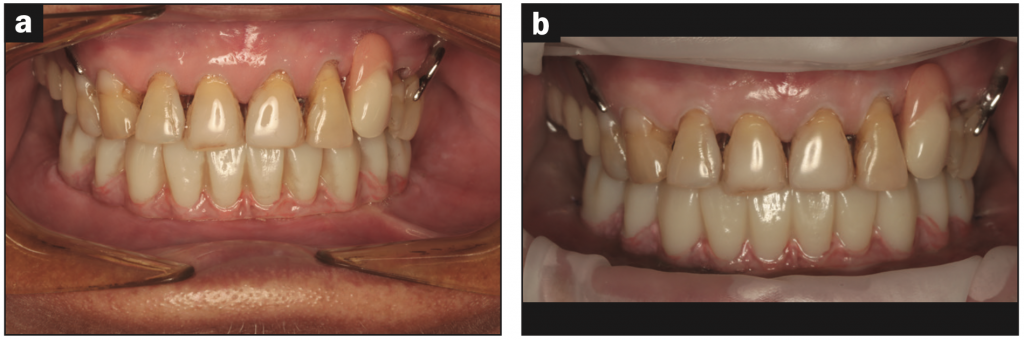

Figure 14. (a) Temporary prosthesis at initial delivery and (b) at 6 months in function prior to proceeding to the definitive restoration.

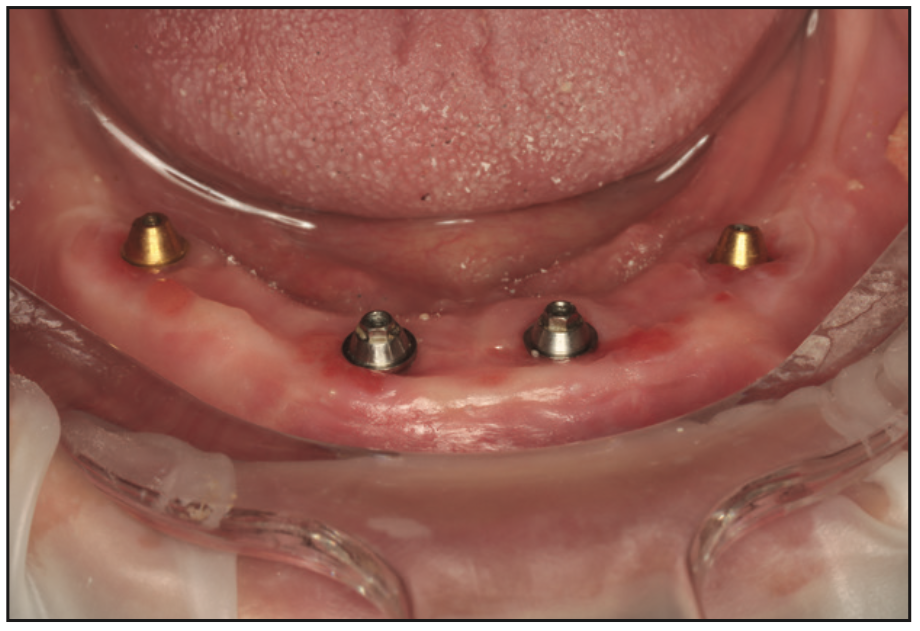

Figure 15. Intraoral situation prior to the definitive restoration.

The photos in Figure 14 show the temporary prosthesis at delivery and at 6 months in function prior to proceeding to the definitive restoration. Figure 15 shows the healing underneath the printed bridge, which demonstrates the biocompatibility of the Rodin material.

REFERENCES

1. Malo P, de Araújo Nobre M, Lopes A, et al. A longitudinal study of the survival of All-on-4 implants in the mandible with up to 10 years of follow-up. J Am Dent Assoc. 2011;142(3):310–20. doi:10.14219/jada.archive.2011.0170

2. Alageel O, Alsadon O, Almansour H, et al. Assessment of effect of accelerated aging on interim fixed dental materials using digital technologies. J Adv Prosthodont. 2022;14(6):360–8. doi:10.4047/jap.2022.14.6.360

3. Ma B, Yue X, Sun Y, et al. Accuracy of photogrammetry, intraoral scanning, and conventional impression techniques for complete-arch implant rehabilitation: an in vitro comparative study. BMC Oral Health. 2021;21(1):636. doi:10.1186/s12903-021-02005-0

ABOUT THE AUTHOR

Dr. O’Dowling graduated from University College Cork, Ireland, in 2006, where he was awarded the Noel Hayes Award for Oral Surgery and the British Undergraduate Society Award for Restorative Dentistry, and he was accepted as a member of the Student Clinicians of the American Dental Association for his project work on molar/incisor hypomineralisation. He has worked in private practice in Ireland and in Queensland and Perth, Australia. During this time, he has continued to advance his knowledge in implant surgery and prosthetics and completed his MSc in Oral Implantology in 2018 from Goethe Dental School (Frankfurt, Germany). He is a Diplomate of both the International Congress of Oral Implantologists and the American Board of Oral Implantology/Implant Dentistry and a Fellow of the American Academy of Implant Dentistry. Dr. O’Dowling maintains a keen interest in all aspects of implantology, ranging from simple implant placement to advanced techniques such as partial extraction therapy, autogenous bone plates, and sinus augmentations. His current focus is the simplification of full-arch restorative protocols utilizing digital techniques and 3D printing. He can be reached at daveodowling83@gmail.com.

Disclosure: Dr. O’Dowling reports no disclosures.