Dentists worldwide are now harnessing the power of 3-D printing technology regularly, and their patients are reaping the benefits.

Advances in 3-D printing have advantages reaching beyond the worlds of construction and technology. Dentists are now using 3-D printing technology for the rapid and chairside production of aligners, dental implant surgery templates, restorative materials, removable dentures, and other patient treatment options.

3-D printing will do more than save your time. It will benefit your patients as well. More importantly, it will help you enhance your productivity and increase your revenues.

Dental 3-D Printing Materials

Dental 3-D printing often uses a process called photopolymerization. This process uses light energy to initiate a polymerization reaction that results in a polymer structure with desired properties. Polyether ether ketone (PEEK) is routinely used in photopolymerization for dental 3-D printing since it is both safe and effective. As strong as steel with 80% less weight, PEEK is an incredibly high-performance thermoplastic that can be formed to fit a patient’s dental needs.

Photopolymerization also includes stereolithography, an alternative 3-D printing method in which monomers are fused to make polymers for larger structures, such as aligners, night guards, dental crowns, and dental retainers.

Another option for stereolithographic dental device formulation is epoxy resin, which is a thermoset plastic, or a material that uses heat energy. Epoxy resins are inexpensive, especially compared to gold or silver, and are entirely insoluble. And as the costs of gold and silver have risen, epoxy resin prices have dropped significantly. Ultimately, 3-D printing may be one of the most affordable ways to produce dental implants and crowns for patients.

Pre-Surgical and Orthodontic Planning

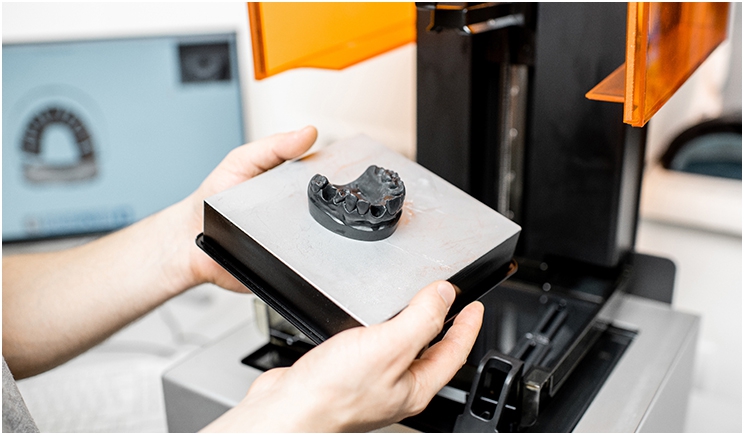

By scanning a patient’s teeth, dental professionals can use software to generate an incredibly accurate 3-D model of a patient’s mouth. In dentistry, dental implants, aligners, and crowns must fit perfectly. Any failure to do so can incur extra time, cost, and patient dissatisfaction.

Using 3-D scanning and printing can drastically reduce the margin for error. It can help make aligners, night guards, and even oral surgery a more streamlined and accurate process.

Also, 3-D scans can help dentists and orthodontists plan out their orthodontic work and preview patient results. In creating an aligner, the dentist or orthodontist uses software to help determine which teeth should be encouraged to move and the timing for each new aligner to make those teeth shift. Dentists can even give their patients a model of their old smile to compare their results once orthodontic treatment has been completed.

3-D Printed Aligners

One of 3-D printing’s most popular uses is for producing aligners and night guards. Aligners have become an incredibly popular alternative to braces due to their near invisibility.

After the 3-D model of a patient’s teeth is produced, a plastic sheet is vacuum fitted over the smart technology model. This model later becomes the first aligner, which guides the patient’s teeth toward their future position. The dentist can also use the 3-D model of the patient’s teeth to model and then 3-D print the aligner.

Either way, these 3-D printed aligners can be produced with great speed. It only takes a couple of hours to design and manufacture a full batch. Due to the precision of 3-D scanning, they are also incredibly accurate and customizable.

Crowns, Bridges, and Dentures

Dental restoration done with 3-D printing can increase the speed and accuracy of the work. With traditional methods, making a dental crown is often a time-consuming, expensive process. However, 3-D printing drastically reduces the time and cost of making crowns. The dentist can scan the broken tooth, use software to create a model of the crown, and print the crown. Suddenly, the process goes from taking weeks to less than a a few hours.

Additionally, dentists can manufacture porous titanium implants with 3-D dental printing. This technology can fuse titanium particulars layer by layer based on an incredibly accurate 3-D scan of the patient’s mouth.

Computerized numerical control (CNC) and 3-D printing technologies enable dentists to perform porcelain restorations with greater ease and accuracy. The planning and scanning of the restoration are done using 3-D printing software, and then the CNC machine can cut the porcelain exactly to the specifications of the patient’s mouth.

Other 3-D Printing Capabilities

There are also applications for 3-D printing in dental surgery. It provides dentists with new tools to help enhance their surgical procedures. For example, a dentist can create a 3-D model of the patient’s mouth and, from there, create a device similar to an aligner.

The only difference is that this aligner has openings exactly where surgical action is needed, such as indicating precisely where dentists need to drill. Dentists can then enhance the speed, precision, and safety of their surgical procedures.

This 3-D printing technology also lets dentists create retainers much more cost-effectively. Dental patients are known for losing retainers after cosmetic dentistry, which has previously been an expensive and time-consuming problem. But 3-D printing can help dentists replace retainers with far greater ease.

Patient Benefits

Patients can enjoy several benefits as a result of 3-D dental printing. Dentists can use 3-D models of patients’ mouths to check their work before placing dental implants, fitting aligners, or using other orthodontic methods.

While accuracy can be enhanced to great patient benefit, so can the speed with which dental devices are manufactured. Patients don’t have to wait for weeks for crowns or aligners. Instead, they can be fabricated in a fraction of the time. This can reduce patient suffering and inconvenience.

Plus, 3-D dental printing can help cut patient costs. Using more sophisticated technologies and materials takes fewer workers, requires less time, and produces less waste. This helps keep the cost of retainers, aligners, implants, and crowns more reasonable.

Of course, the patient’s benefits lead to advantages for the dentist who uses 3-D dental printing technologies. Successful utilization of 3-D dental printing can help give your practice a reputation for affordability and excellent patient care. That’s the kind of good reputation that will spread and bring a dentist more clients.

Final Thoughts

3-D printing is revolutionizing the dental industry. As more dentists adopt this technology, the costs of 3-D printers and materials will come down. This can help cut customer costs even further, which means that patients will benefit enormously from the widespread use of 3-D printing technology at their dentist’s practice.

Dr. Swaida first graduated from the University of Western Ontario with an honors BSc in biology before graduating from the University of Manitoba’s Faculty of Dentistry. He is an active member of his church and enjoys football and being by the water! His outgoing personality and fun-loving character will ensure you always feel welcome at Dental Implants Clinic. He can be reached at editor@dentistnorthyork.com.

Related Articles

The Eight Qualities of Great Customer Service in Dentistry

Collaboration Is Key to Advancing Innovation in Dentistry

3-D Printing Resin Designed for Permanent Crowns