INTRODUCTION

In the early 1990s, the use of nickel-titanium (NiTi) alloy to manufacture engine-driven instruments for shaping root canals moved endodontics to a different level. Practitioners, universities, and companies started unprecedented cooperation to understand the countless advantages that adopting this unique metal alloy could provide for the evolution of the instrumentation technique.

As a result, the last 3 decades have seen an explosion in the development of NiTi endodontic file systems, and tremendous progress has been made. Improvements in metallurgical technology allowed the development of various new instruments with innovative designs, blade geometries, and alloy thermomechanical treatments, resulting in improved efficiency.1-7

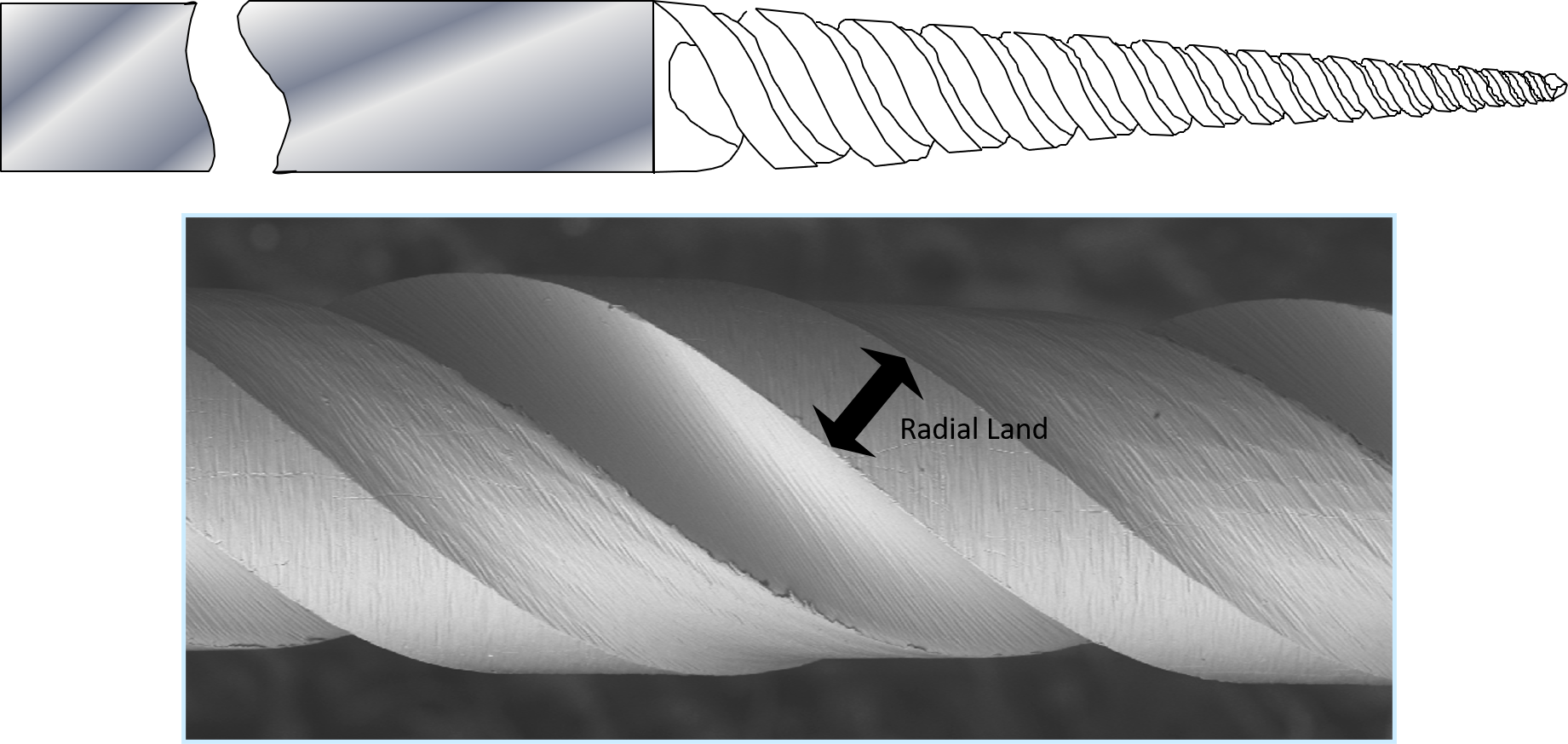

NiTi rotary instruments for the mechanized preparation of root canals were developed by John McSpadden and Ben Johnson in 1990. The first-generation NiTi rotary files were characterized by instruments having passive cutting radial land (Figure 1), constant taper, and a neutral or negative rake angle. Examples of the first generation are McXim File (NT Company), GT system (Dentsply Sirona), LightSpeed (LightSpeed Technology), Pow-R (Moyco), ProFile (Dentsply Sirona), and Quantec (Tycom). The primary deficiencies of the systems in this group were the number of instruments required to achieve the complete canal preparation and the rather complex protocols needed.

Figure 1. Blade of a first-generation engine-driven file. The double arrow shows the radial land.

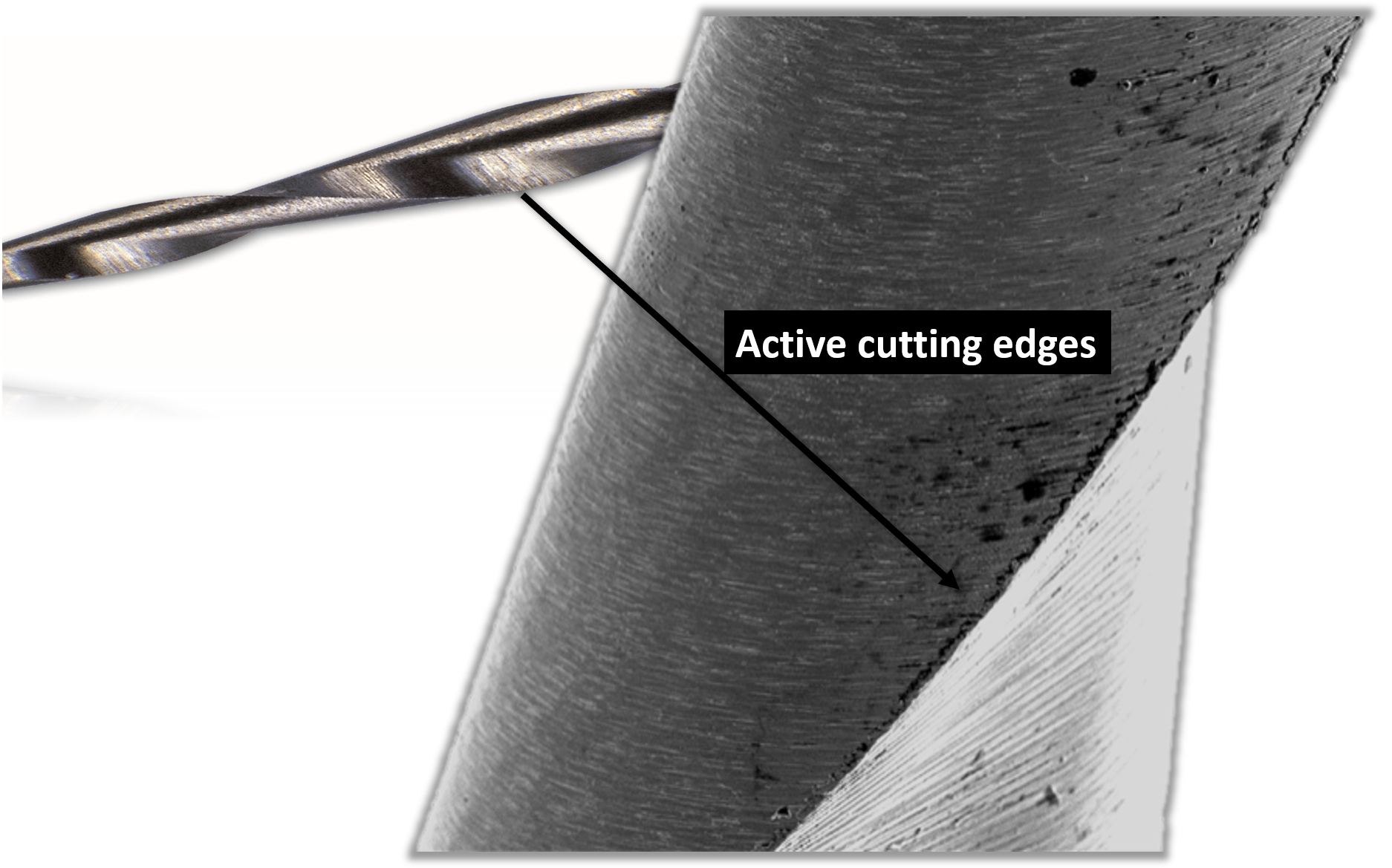

The second generation of NiTi engine-driven files appeared at the end of the 1990s. Instruments were manufactured with changes in their helical angles, tapers, and cutting angles. As a result, this generation’s engine-driven files had active cutting edges (Figure 2), improving their efficiency, and most of them were without radial land.

Figure 2. Second-generation file showing modifications on the cutting surface.

These enhancements led to fewer instruments required to accomplish complete canal preparation. In addition, some manufacturers applied a supplemental treatment on the file surface called electropolishing (EP). EP removes surface irregularities, cracks, and residual stress caused by the previous grinding process.8 However, only one study found that EP significantly reduces the resistance to cyclic fatigue while increasing the angle of deflection at failure.9

Examples of the second generation are EndoSequence (Brasseler), K3 (Sybron), ProTaper Universal (Dentsply Sirona), and Genius (Medidenta). Despite requiring fewer instruments, fractures were still a significant concern, and preliminary clinical guidelines were recommended, such as glide path and coronal preflaring, which reduced the occurrence of file separations.

In 2007, post-grinding thermomechanical procedures began to be used by the leading manufacturers initiating the third generation of instruments. Each company developed a different heat treatment method. Following the implementation of these technologies, the engine-driven files became safer, with enhanced performance in shaping ability, especially in the preparation of anatomical challenges, such as curved canals. At the same time, clinical studies reported lower fracture rates using these heat-treated files.10,11

Examples of the latest generation are HyFlex CM (Coltène), K3XF (SybronEndo), ProFile Vortex Blue (Dentsply Sirona), ProTaper Ultimate (Dentsply Sirona), ZenFlex (Kerr), EdgeTaper Platinum (EdgeEndo), and Genius Proflex (Medidenta).

THE RATIONALE FOR HEAT-TREATED NITI FILES

Originally, NiTi alloy was developed by the Naval Ordnance Laboratory (White Oak, Md) and named Nitinol, an acronym for nickel (Ni), titanium (Ti), and Naval Ordnance Laboratory (NOL). NiTi alloy used in endodontic instruments contains approximately 56 wt% nickel and 44 wt% titanium, resulting in a nearly one-to-one atomic ratio (equiatomic).12

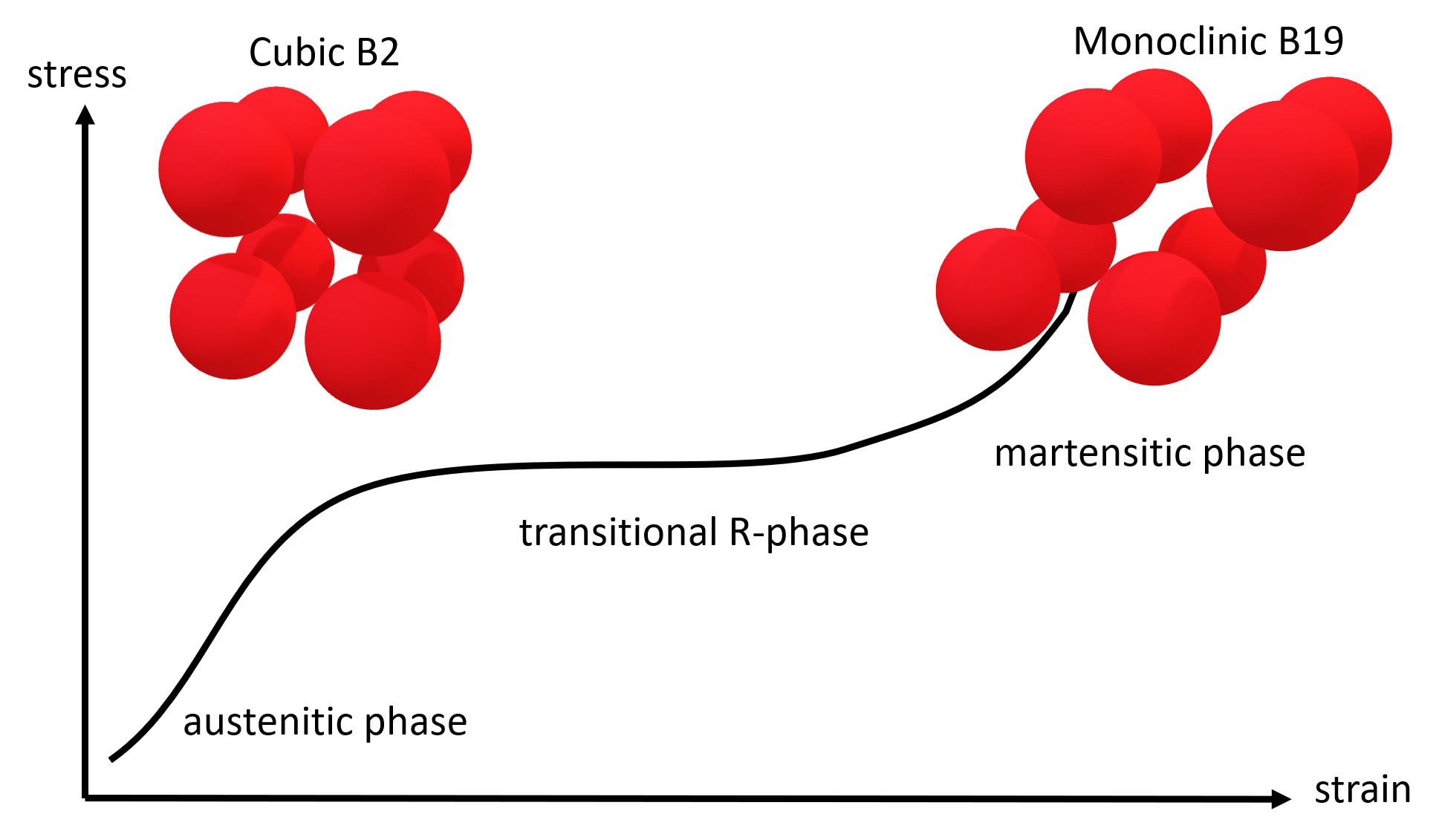

This equiatomic NiTi alloy can exist in 2 different strain- and temperature-dependent crystal structures (Figure 3) called austenitic (cubic B2 crystal structure) and martensitic (monoclinic B19 crystal structure) phases.13

Figure 3. NiTi alloy phase expressions (austenitic, transitional R-phase, and martensitic) with representations of the different atomic crystal structures.

Heat treatment is one of the fundamental approaches to adjust the crystalline transition phase of a metal alloy and improve its fatigue resistance. This modification is essential because several properties of each alloy phase expression are notably different. For example, the proportions of the austenitic phase (more rigid and with the spring-back effect) and martensitic phase (more flexible with permanent plastic deformation) determine different instrument performances.

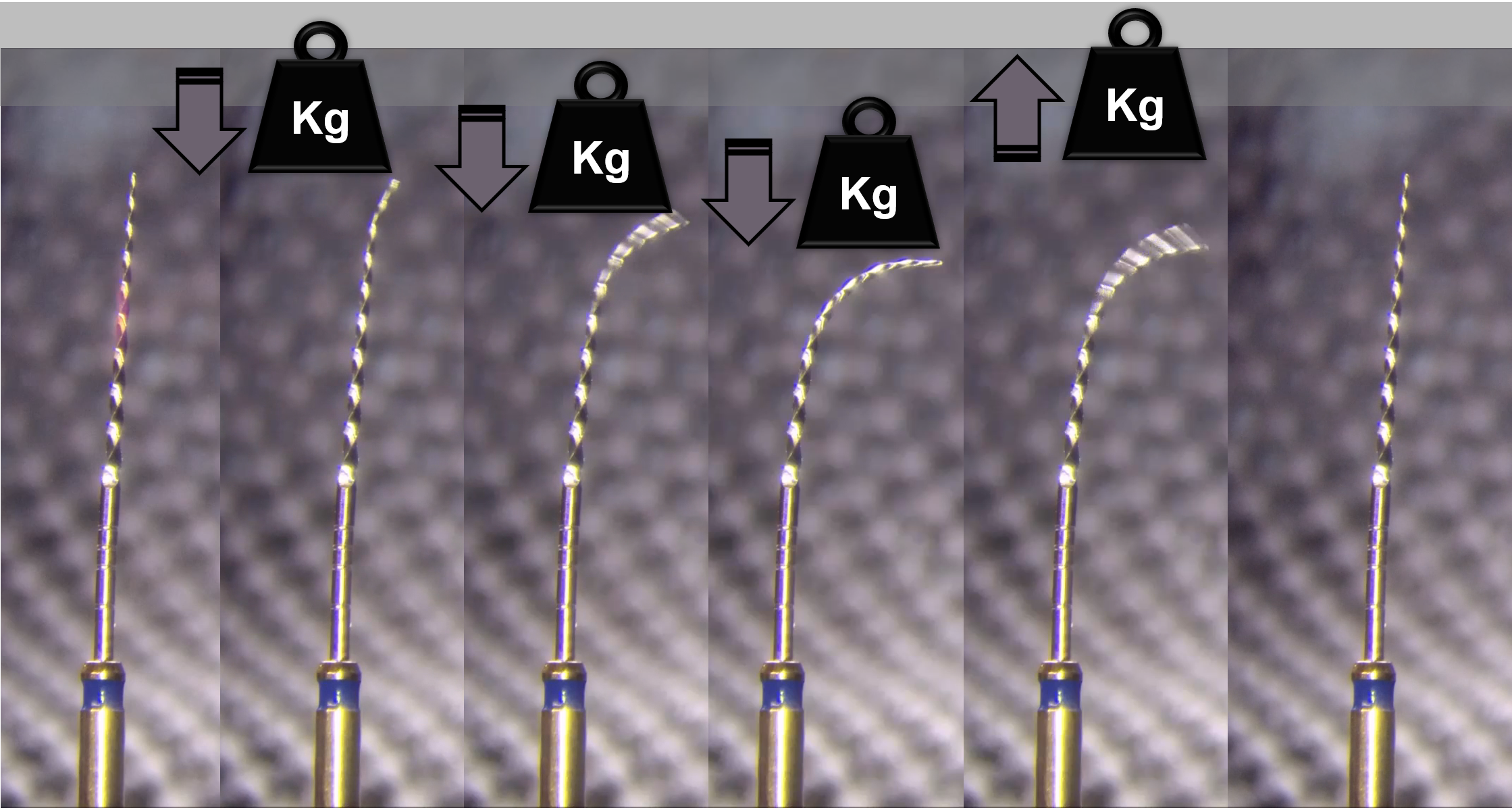

The file is soft when the alloy is in its martensitic phase, and it can easily be permanently bent (also defined as controlled memory). In contrast, the austenitic phase is firm and returns to the original straight condition when the load is removed (spring-back effect, see Figure 4). From a practical point of view, martensitic instruments are recommended to be used in curved canals once they are supposed to provide better maintenance of the original canal path.14-17

Figure 4. Representation of the spring-back effect. The applied load will deform the file temporally. However, the file returns to its original, straight position once the load is removed.

The major limitation of controlled memory (CM) instruments is that the martensitic alloy phase expression requires less load for deformation, meaning that the unwinding of CM files can be experienced more often, particularly in the initial prospection phase of instrumentation with small-diameter files.

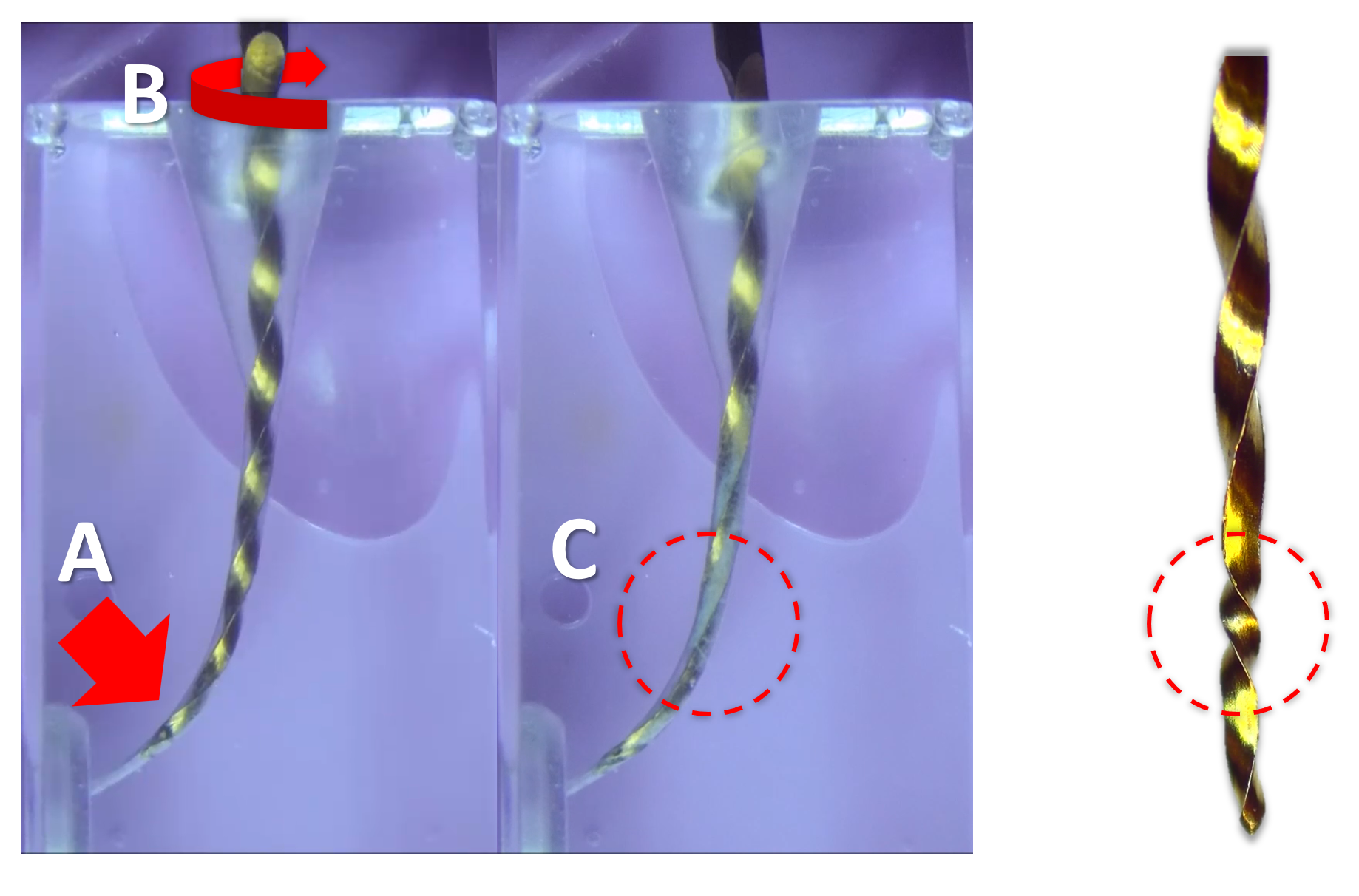

In addition, predominant martensitic alloy phase expression under torsion has a high angular deflection to sustain great rotation before fracture (Figure 5); however, the torque needed to deform and fracture these instruments is lower than with austenitic instruments.18-22

Figure 5. Representation of torsional load without separation on a martensite file. (a) The file tip locks inside the canal’s narrowest segment, (b) but the motor continues the clockwise file rotation. (c) The martensitic characteristic of high angular deflection allows [SC: for?]unwinding, visible deformation without separation.

Therefore, instruments whose alloys are mainly in the martensitic phase have more flexibility to deal with curvatures, but they tend to have more significant distortion in the face of forces contrary to their progress in the apical direction. It is concluded that the martensitic phase would be more attractive in instruments of a higher caliber, above 25 (ISO 25), for example.

In these instruments, the greater metallic mass factor influences flexibility negatively yet, in the meantime, collaborates with their resistance to harmful torsional fatigue. The martensitic alloy phase expression given by the heat treatment can help flexibility without decreasing the torsional strength.

Different factors regarding torsional stress generation during root canal preparation have been identified in the literature. These include the type of canal curvature, instrument design and cutting efficiency, instrument size and canal size, contact area, preparation technique, preparation time, insertion depth and the number of insertions, correlation with displacement, motor source, kinematics, operative motion type, rotational speed and pecking speed, lubricant, experience, and alloy phase expression.23

NiTi rotary files with high expression of the austenitic alloy phase will have more torsional fatigue resistance.24 The alloy in a predominant austenitic phase expression is more suitable for thinner instruments, with a 20 (ISO 20) diameter or lower. Moreover, these instruments have lower metallic mass, leading to a natural flexibility that is given to the small diameter.

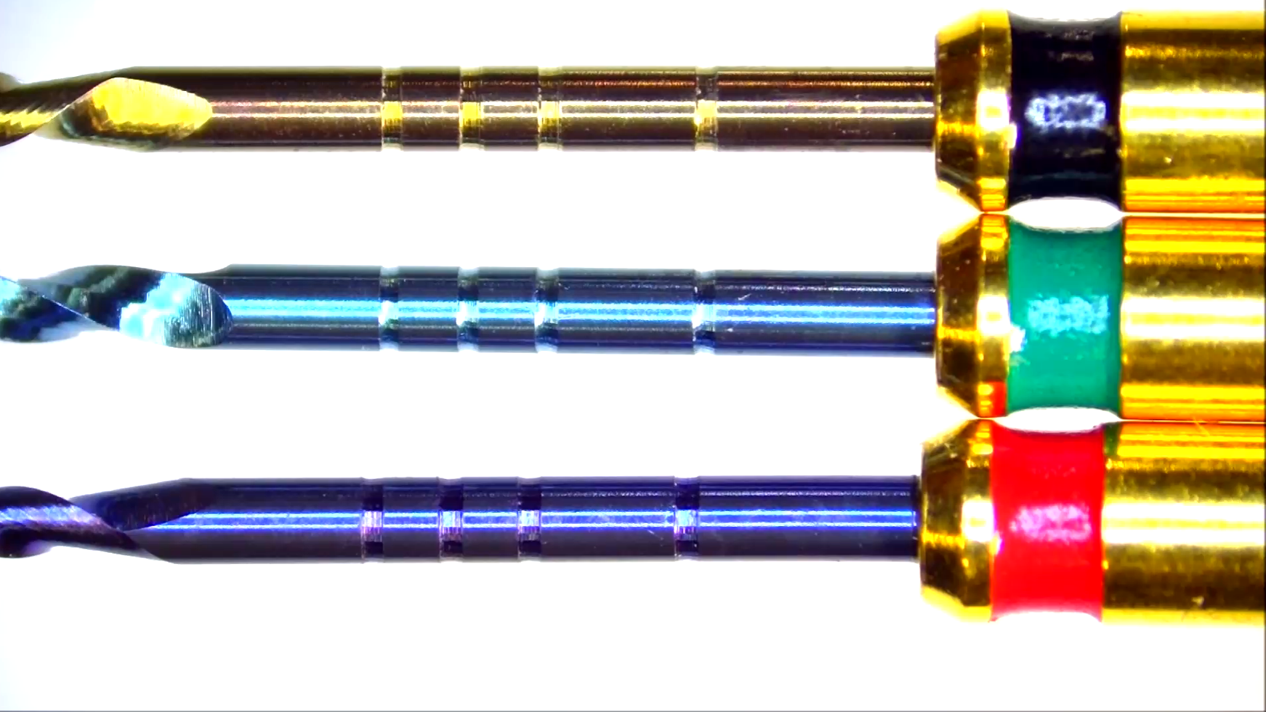

An interesting consequence of the various heat treatments in a NiTi alloy is the deposition of titanium oxide layers on the external surface of the instrument blade. Differences in the thicknesses of these layers are responsible for changing the exterior color of the instrument blade (Figure 6), which can be presented with different hues of violet, blue, or gold.25

Some heat treatment formulas do not necessarily lead to the formation of a titanium oxide layer relevant enough to change the instrument’s color, such as M-Wire (Dentsply Sirona).

Figure 6. Gold, blue, and violet blade colors due to different heat treatments that were applied (Genius Proflex [Medidenta]).

PURSUING THE RIGHT BALANCE BETWEEN FLEXIBILITY AND RESISTANCE: THE CUSTOMIZED HEAT TREATMENT

Instruments whose alloys are entirely in the austenitic phase have limited indications. For example, an instrument that is less prone to torsional fatigue may be desired in cases of retreatment, where the force exerted against the filling material to be removed results in a more significant torsional load on the instrument. However, these instruments, also known as super elastic (SE), have less flexibility and are more susceptible to cyclic fatigue fracture.

In addition, a slight deformation in the face of torsional forces is welcome, showing the operator that the force applied to the instrument’s progression is too great and there is an imminent danger of fracture. For instance, suppose the instrument locks within the canal walls and continues to rotate at a high torque.

In that case, it will inevitably reach its elastic resistance limit, and a torsional fracture will occur.

Therefore, it would be fair to say that the operator should choose an instrument alloy phase expression that is more austenitic for files during the initial apical approach, such as glide path instruments or smaller diameter instruments, as flexibility would be present due to the design and metallic mass. In contrast, these instruments need a performance surplus due to torsional fatigue resistance by a higher angular deflection.

On the contrary, files of greater caliber should present their alloy phase expressions in a more martensitic phase given their greater volume in mass and lesser flexibility. It is worth remembering that fully austenitic instruments must be relegated to specific functions, such as retreatment. If the same heat treatment is performed for all sizes, some will benefit from the accomplished metallurgical changes while others will be harmed. Therefore, one method doesn’t equally satisfy the needs for all sizes.

Until mid-2020, the scenario was that if the operator wanted to get the most out of heat treatment in endodontic instruments, he or she would have to mix and match different systems. However, considering that “other systems” implies a different protocol sequence and that no consensus or research is showing the results of this mix of instruments, evaluating the quality and safety of this mix-and-match option seems to be entirely empirical and only based on individual experiences.

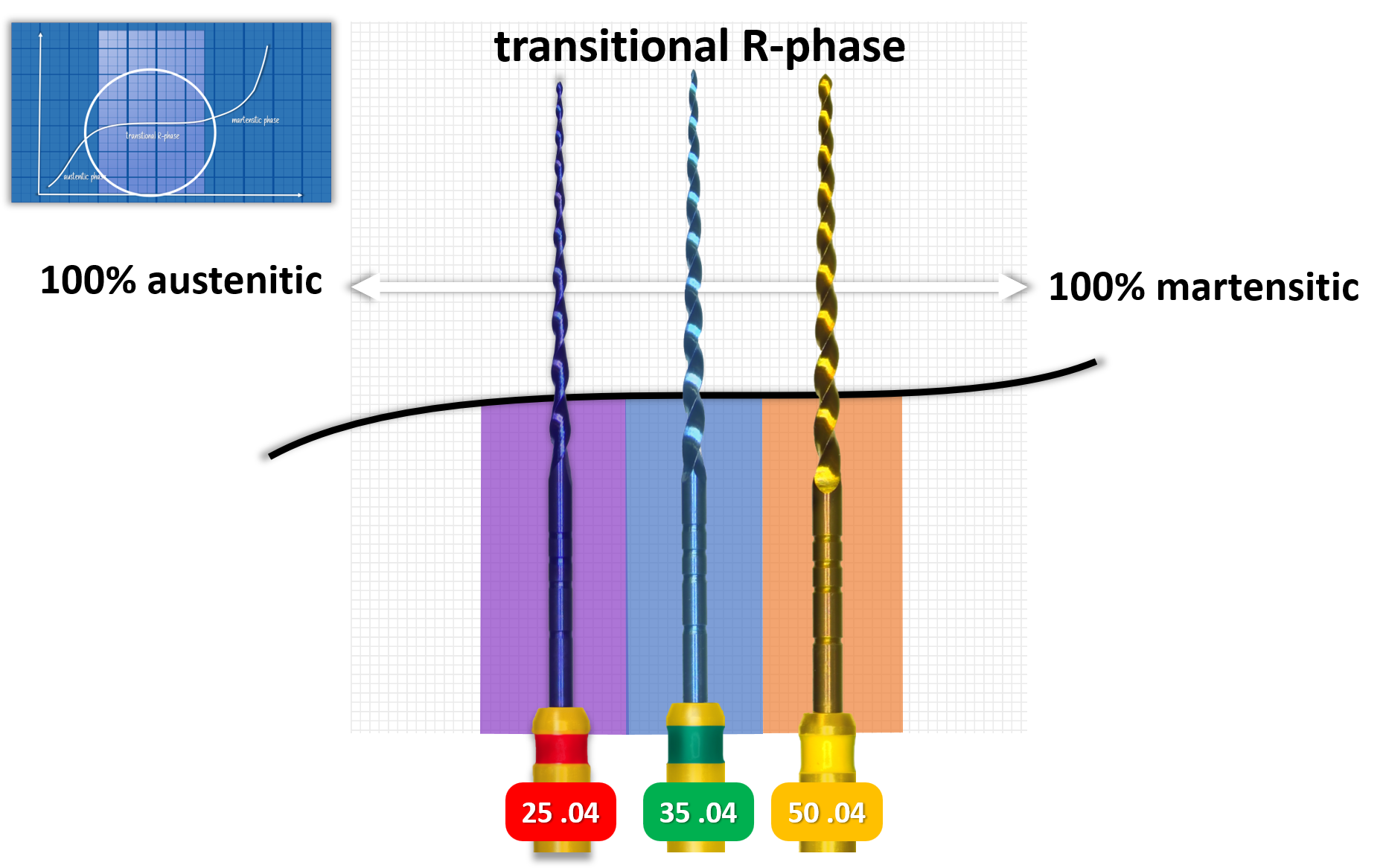

Genius files were established in 2015 with a design that allowed rotary and asymmetrical reciprocal motion use. The improved generation of Genius files, Genius Proflex (Medidenta), was launched in 2020 as the first system to adopt customized heat treatments (Figure 7) to balance torsional strength and high flexibility in different sizes of files.

Figure 7. Genius Proflex file examples of the 3 different heat treatments applied. Small-diameter files (purple) received a more austenitic heat treatment, intermediate files (blue) received a more martensitic treatment, and larger files (gold) received the higher martensitic heat treatment.

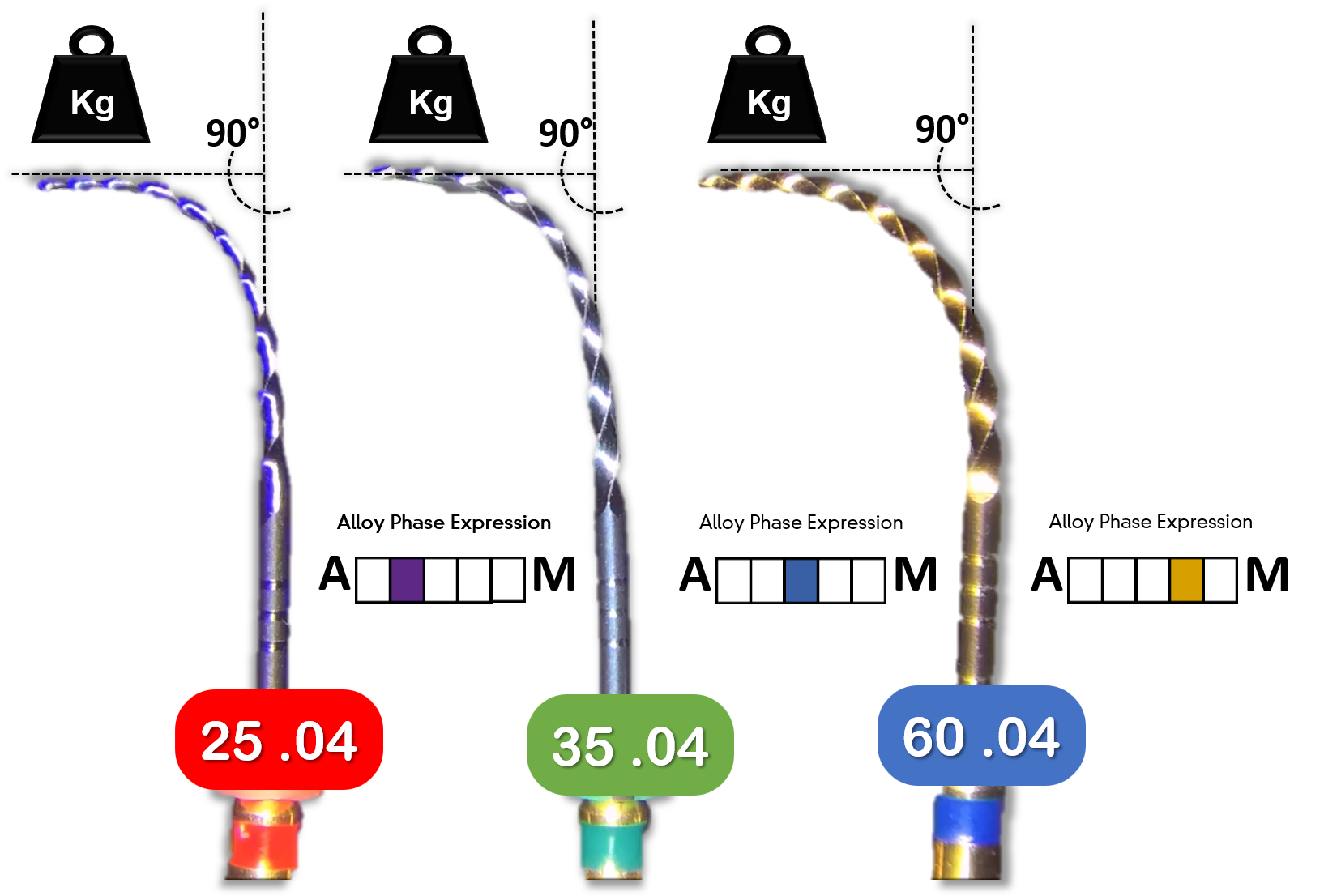

With new instruments in the series and 3 tailored heat treatments, Genius Proflex showed a better balance between torsional resistance (more austenitic in the smaller caliber files) and higher flexibility (more martensitic in the larger caliber files) (Figure 8).

Figure 8. As a result of the customized heat treatments applied for different diameters of files, Genius Proflex large files present a more martensitic alloy expression phase showing the same flexibility as the small-diameter files, which naturally offer more flexibility due to less metallic mass.

The thinner (ISO 13 .03, 17 .05, and 25 .04) instruments received a heat treatment with a more dominant austenitic phase, which led to a violet stain. The more martensitic, larger files (ISO 40 .04, 50 .04, and 60 .04) resulted in a golden color. There are also 2 intermediate instruments (ISO 30 .04 and 35 .04) whose heat treatment resulted in a bluish hue.

This mix of heat treatments leads to a differentiated performance of each instrument in the series, increasing resistance to the 2 biggest challenges presented during instrumentation (torsional and cyclic fatigue) at different stages of treatment.

It seems that there is a trend toward customized heat treatments based on the metallic mass of the instrument. Since the launch of Genius Proflex in 2020, other manufacturers have presented systems with a differentiated heat treatment in the sequence, corroborating the original idea that the same heat treatment should not merely be applied to different file sizes.

One example is an instrument ISO 15 .04 whose alloy is in the martensitic phase. Indeed, the operator will have a lot of difficulties advancing apically given the high degree of distortion and ineffectiveness of the cut of this instrument.

Clinically, the instrument has an angular deflection angle up to the fracture that is so high that the instrument distorts, even before the dentin walls are cut, and the canal widens.

CLOSING COMMENTS

Instrument separation during shaping procedures with rotary NiTi systems is an undesired event that can lead to complex resolutions. The wide range of fracture rates reported in the literature (from 1.98% to 26%) highlights the unpredictability of this phenomenon in clinical practice. It could certainly be related to multiple factors, such as instrument design, number of uses, motor kinematics, root canal anatomy, or operator experience.

Extensive clinical and scientific knowledge was created about the benefits of file heat treatments and the predominant phases acquired. It is essential to know that different heat treatments lead to various instrument performances, helping to overcome the separation of instruments in different stages of instrumentation.

REFERENCES

1. Gavini G, Santos MD, Caldeira CL, et al. Nickel-titanium instruments in endodontics: a concise review of the state of the art. Braz Oral Res. 2018;32(suppl 1):e67. doi:10.1590/1807-3107bor-2018.vol32.0067

2. Haapasalo M, Shen Y. Evolution of nickel-titanium instruments: from past to future. Endod Topics. 2013;29:3–17. doi:10.1111/etp.12049

3. Peters OA. Current challenges and concepts in the preparation of root canal systems: a review. J Endod. 2004;30(8):559–67. doi:10.1097/01.don.0000129039.59003.9d

4. Shen Y, Coil JM, Zhou H, et al. HyFlex nickel-titanium rotary instruments after clinical use: metallurgical properties. Int Endod J. 2013;46(8):720–9. doi:10.1111/iej.12049

5. Shen Y, Zhou HM, Zheng YF, et al. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J Endod. 2013;39(2):163–72. doi:10.1016/j.joen.2012.11.005

6. Zhou H, Peng B, Zheng YF. An overview of the mechanical properties of nickel-titanium endodontic instruments. Endod Topics. 2013;29:42–54. doi:10.1111/etp.12045

7. Zupanc J, Vahdat-Pajouh N, Schäfer E. New thermomechanically treated NiTi alloys – a review. Int Endod J. 2018;51(10):1088-1103. doi:10.1111/iej.12924

8. Kuhn G, Tavernier B, Jordan L. Influence of structure on nickel-titanium endodontic instruments failure. J Endod. 2001;27(8):516–20. doi:10.1097/00004770-200108000-00005

9. Bui TB, Mitchell JC, Baumgartner JC. Effect of electropolishing ProFile nickel-titanium rotary instruments on cyclic fatigue resistance, torsional resistance, and cutting efficiency. J Endod. 2008;34(2):190–3. doi:10.1016/j.joen.2007.10.007

10. Shen Y, Zhou HM, Zheng YF, et al. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J Endod. 2013;39(2):163–72. doi:10.1016/j.joen.2012.11.005

11. Gambarini G, Piasecki L, Di Nardo D, et al. Incidence of deformation and fracture of twisted file adaptive instruments after repeated clinical use. J Oral Maxillofac Res. 2016;7(4):e5. doi:10.5037/jomr.2016.7405

12. Thompson SA. An overview of nickel-titanium alloys used in dentistry. Int Endod J. 2000;33(4):297-310. doi:10.1046/j.1365-2591.2000.00339.x

13. Buehler W, Gilfrich J, Wiley RC. Effects of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. Int J Appl Phys. 1963;34:1475–7. doi:10.1063/1.1729603

14. Sousa-Neto MD, Silva-Sousa YC, Mazzi-Chaves JF, et al. Root canal preparation using micro-computed tomography analysis: a literature review. Braz Oral Res. 2018;32(suppl 1):e66. doi:10.1590/1807-3107bor-2018.vol32.0066

15. Arslan H, Yildiz ED, Gunduz HA, et al. Comparative study of ProTaper gold, reciproc, and ProTaper universal for root canal preparation in severely curved root canals. J Conserv Dent. 2017;20(4):222–4. doi:10.4103/JCD.JCD_94_17

16. Bürklein S, Hinschitza K, Dammaschke T, et al. Shaping ability and cleaning effectiveness of two single-file systems in severely curved root canals of extracted teeth: Reciproc and WaveOne versus Mtwo and ProTaper. Int Endod J. 2012;45(5):449–61. doi:10.1111/j.1365-2591.2011.01996.x

17. Plotino G, Ahmed HM, Grande NM, et al. Current assessment of reciprocation in endodontic preparation: a comprehensive review–part II: properties and effectiveness. J Endod. 2015;41(12):1939–50. doi:10.1016/j.joen.2015.08.018

18. Silva EJNL, Vieira VTL, Belladonna FG, et al. Cyclic and torsional fatigue resistance of XP-endo shaper and TRUShape instruments. J Endod. 2018;44(1):168–72. doi:10.1016/j.joen.2017.08.033

19. Silva EJNL, Giraldes JFN, de Lima CO, et al. Influence of heat treatment on torsional resistance and surface roughness of nickel-titanium instruments. Int Endod J. 2019;52(11):1645–51. doi:10.1111/iej.13164

20. Silva EJNL, Hecksher F, Antunes HDS, et al. Torsional fatigue resistance of blue-treated reciprocating instruments. J Endod. 2018;44(6):1038–41. doi:10.1016/j.joen.2018.03.005

21. Silva EJNL, Vieira VTL, Hecksher F, et al. Cyclic fatigue using severely curved canals and torsional resistance of thermally treated reciprocating instruments. Clin Oral Investig. 2018;22(7):2633–38. doi:10.1007/s00784-018-2362-9

22. Pedullà E, Lo Savio F, Boninelli S, et al. Torsional and cyclic fatigue resistance of a new nickel-titanium instrument manufactured by electrical discharge machining. J Endod. 2016;42(1):156–9. doi:10.1016/j.joen.2015.10.004

23.Thu M, Ebihara A, Adel S, et al. Analysis of torque and force induced by rotary nickel-titanium instruments during root canal preparation: a systematic review. Appl Sci. 2021;11:3079 doi:10.3390/app11073079

24.Lopes HP, Gambarra-Soares T, Elias CN, et al. Comparison of the mechanical properties of rotary instruments made of conventional nickel-titanium wire, M-wire, or nickel-titanium alloy in R-phase. J Endod. 2013;39(4):516–20. doi:10.1016/j.joen.2012.12.006

25.Tian H, Schryvers D, Liu D, et al. Stability of Ni in nitinol oxide surfaces. Acta Biomater. 2011;7(2):892–9. doi:10.1016/j.actbio.2010.09.009

ABOUT THE AUTHOR

Dr. Ramos received his DDS degree from the State University of Londrina in Brazil in 1987. He has a PhD in endodontics and is a former head of the endodontics department at the State University of Londrina. He has published 3 endodontic textbooks and has written more than a dozen chapters for various endodontic books. Living in the United States since 2012, Dr. Ramos lectures globally about streamlined endodontic protocols. He can be reached via email at carlos.ramos@medidenta.com.

Disclosure: Dr. Ramos is the director of clinical affairs for Medidenta.