Many high-strength ceramic systems have recently emerged on the dental market. Of these, Cercon Zirconia (DENTSPLY/Ceramco) has proven its durability and aesthetics to the dental community since 1998.1 The recent launch of Cercon Art (DENTSPLY/Ceramco) has made the predictability of a precision fit available to dental laboratories.2 Cercon is used for a wide variety of restorations, from single units to long-span bridges; Cercon Art is a new computer-aided design (CAD) module for the Cercon system. A CAD/CAM system can deliver predictable fit with excellent aesthetics, as the case studies presented will demonstrate.

Cercon Art: CAD/CAM in the Dental Laboratory

Cercon Zirconia is an excellent material choice for metal-free restorations because of its biocompatibility, strength, and durability.3,4 It has been proven in clinical studies for more than 8 years. The news about the durability of this material is very promising. Research shows in vitro performance equivalent to PFM restorations.5 A new study of subcritical crack growth in Cercon Zirconia predicts a possible 20-year lifetime for the material.6

The challenge with processing zirconia in a dental lab is control of shrinkage. Until recently dental technicians have had to create a wax model of a restoration to be scanned by the precision laser of the Cercon system. The general fit of the restorations was acceptable and in the range of PFM restorations.7 However, this was still a labor issue for laboratories, in this time of skilled labor shortages.

The recent development of Cercon Art CAD has brought automated and repeatable predictability and computer precision to the process. The Cercon Art computer program is intuitive and allows for the fabrication of copings customized for cement gaps, wall thickness, and occlusal geometry. This technology offers the dental laboratory a cost-effective means to fabricate single units without resorting to outsourcing. This also represents a significant time-savings for the dental laboratory versus the hand wax coping method, as there are no interferences or tight fits that the technician has to hand-finish.

The fit of Cercon restorations are now in the 50-µm to 80-µm range.8 The CAD program reduces the effect of human variability, which allows for more consistency from the dental laboratory. What is of particular interest to this active clinician is that Cercon Art CAD will allow the cement gap to be adjusted to between 10 and 60 µm. A spacer parameter extends the cement gap up to 90% of the surface area. The cement gap is set to a default of 50 µm. You can now seat a relatively passive fit restoration or a precision tight restoration, depending on your choice. As always, communicating your preferences to your dental laboratory is indispensable in getting the results you want.

Clinical Case No. 1

|

|

|

Figure 1. Two maxillary central incisors with leakage. |

Figure 2. Central incisors prepared for Cercon Art. |

|

|

|

Figure 3. Occlusal view, Cercon preparation. |

Figure 4. Cercon Art precision fit before Ceramco layering porcelain. |

|

|

|

Figure 5a. Cercon Art restorations on dies. |

Figure 5b. CerconÌs natural beauty. |

|

|

Figure 6. Cercon Art cemented to place on 2 central incisors. |

A 54-year-old female presented with 2 failing crowns on her central incisors. She also thought her central incisors were too wide and was dissatisfied with proportions as well (Figure 1). A variety of aesthetic materials could have been used in this case, especially in a lower stress anterior situation. I wanted to evaluate not only the fit but the aesthetic potential of Cercon and the Ceramco PFZ layering porcelain.

The older feldspathic material was removed from the 2 central incisors. A conservative, 1-mm marginal and facial finish was prepared for the Cercon and the Ceramco PFZ layering porcelain (Figures 2 and 3). A polyvinyl impression material (Aquasil [DENTSPLY Caulk]) was used to take the impression. The bis-acryl provisionals were made with Integrity (DENTSPLY Caulk).

The Cercon Art CAD system was used to scan the die for both central incisors (Figure 4). This will ensure an adequate marginal fit with Cercon Zirconia. The predetermined coping thickness of 0.4 mm appears to be an optimal balance between strength and translucency.

The completed restorations were inspected on the dies before placement. The patient was anesthetized, and the provisionals were removed. I prefer to evaluate the aesthetics both on a neutral black background and on a die model incorporating gingival simulation (Figures 5a and 5b). After verifying the fit, the interior aspect of the Cercon was microetched by the laboratory with 50-µm aluminum oxide at 2 to 3 bars. This creates micro-mechanical retention for the luting cement. The teeth were scrubbed with chlorhexidine and rinsed. The teeth were then treated with phosphoric acid for 15 seconds and rinsed. A generous coat of Prime & Bond NT (DENTSPLY Caulk) was placed on the prepared teeth and then lightly air-dried and cured for 10 seconds.

Calibra luting cement (DENTSPLY Caulk) was placed in each crown and placed firmly on the teeth. The gingival margins of each crown were tacked to place for approximately 3 seconds. The teeth were carefully flossed and completely cured for 40 seconds on the facial and 40 seconds on the lingual. The excess cement was cleaned off with a scaler, and the margins were polished with an Enhance cup (DENTSPLY Caulk; Figure 6). The patient was instructed in home care and dismissed.

Clinical Case No. 2

|

|

|

Figure 7. Broken anterior bridge. |

Figure 8. Teeth prepared for Cercon bridge and crowns. |

|

|

|

Figure 9. Cercon restorations before Ceramco PFZ porcelain layering. |

Figure 10. Cercon Art bridge and crowns before cementation. |

|

|

Figure 11. Final Cercon Art bridge and crowns in place. |

A 48-year-old male presented with a porcelain-fused-to-metal bridge on tooth Nos. 8 to 10 with the abutment No. 8 broken. Part of the veneering porcelain had sheared away, exposing the metal core. There was interproximal decay on tooth Nos. 5, 6, and 11, with extensive wear on the opposing dentition due to a poorly fitted bridge (Figure 7).

Cercon Zirconia is a good choice for an anterior bridge because the connector size required is significantly smaller (3×3 mm) than lithium disilicate options (5×4 mm). The reduced connector size allows for a more natural-looking bridge. Tooth Nos. 5 to 12 were prepared, with the bridge extending from Nos. 8 to 11. Tooth Nos. 5 to 7 and 12 were single units (Figure 8). Tooth reductions were about 1-mm axial and 1.6-mm occlusal, comparable to those in Case No. 1.

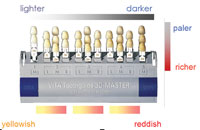

Cercon Art was also used to achieve a more accurate fit for the single units (Figure 9). The patient requested a lighter shade for his restorations, with plans to restore the worn lower teeth after the upper Cercon bridge was completed. CeramcoÌs PFZ porcelain was veneered to the Cercon copings to achieve a lighter (B2) but still natural shade. Since this material is leucite free, lower abrasion levels may be expected on the antagonists.

After removing the provisionals the fit and aesthetics were verified. The internal aspects of the Cercon restorations were blasted with aluminum oxide, and the cementation protocol was the same as in clinical Case No. 1 (Figures 10 and 11).

Summary

The Cercon Zirconia system has opened up new avenues of restorative possibilities for the clinician. This system provides extraordinary strength and beauty with the capability of providing long-span metal-free bridges as well as single crowns. The addition of Cercon Art with its consistency of fit has reduced some of the stresses associated with fabrication and fit issues for the dental technician, and the dentist is assured of delivering an aesthetic product with predictable restorative results.

Acknowledgment

The author would like to acknowledge Ray Foster, CDT, at Las Vegas Esthetics Dental Lab for his dental lab work.

References

1. Sturzenegger B, Feher A, Luthy H, et al. Clinical study of zirconium oxide bridges in the posterior segments fabricated with the DCM system [in German]. Schweiz Monatsschr Zahnmed. 2000;110:131-139.

2. von Schroeter P, Jurgensen B, Zollner M. Cercon move: a navigation aid for dental CAD applications. Int J Comput Dent. 2004;7:371-377.

3. Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999;20:1-25.

4. Filser F, Kocher P, Weibel F, et al. Reliability and strength of all-ceramic dental restorations fabricated by direct ceramic machining (DCM) [published correction appears in Int J Comput Dent. Jul 2001;4:184]. Int J Comput Dent. Apr 2001;4:89-106.

5. Kilicarslan MA, Kedici PS, Kucukes-men HC, et al. In vitro fracture resistance of posterior metal-ceramic and all-ceramic inlay-retained resin-bonded fixed partial dentures. J Prosthet Dent. 2004;92:365-370.

6. Studart AR, Filser F, Kocher P, et al. Cyclic fatigue in water of veneer-framework composites for all-ceramic dental bridges. Dent Mater. Feb 2006; [Epub ahead of print].

7. Ariko K. Evaluation of the marginal fitness of tetragonal zirconia polycrystal all-ceramic restorations [in Japanese]. Kokubyo Gakkai Zasshi. 2003;70:114-123.

8. Piwowarczyk A, Lauer HC. Determining the marginal fit of CAD/CAM bridge frameworks. Presented at: IADR Pan European Federation 2006; September 13-16, 2006; Dublin, Ireland. Abstract 0254.

Dr. Poss is recognized internationally for his work in the field of aesthetic dentistry. He lectures internationally, is published in leading dental journals, and is an active consultant to several dental manufacturers for new product development and refinement. Dr. Poss served as clinical director at the Las Vegas Institute for Advanced Dental Studies from 1998 to 2002. He received his DDS from the University of Tennessee and has received extensive postgraduate train-ing from Baylor University of Contemporary Aesthetic Diagnosis and Treat-ment in Dallas. He can be reached at (615) 373-1056 or drposs@smilesby-design.com.